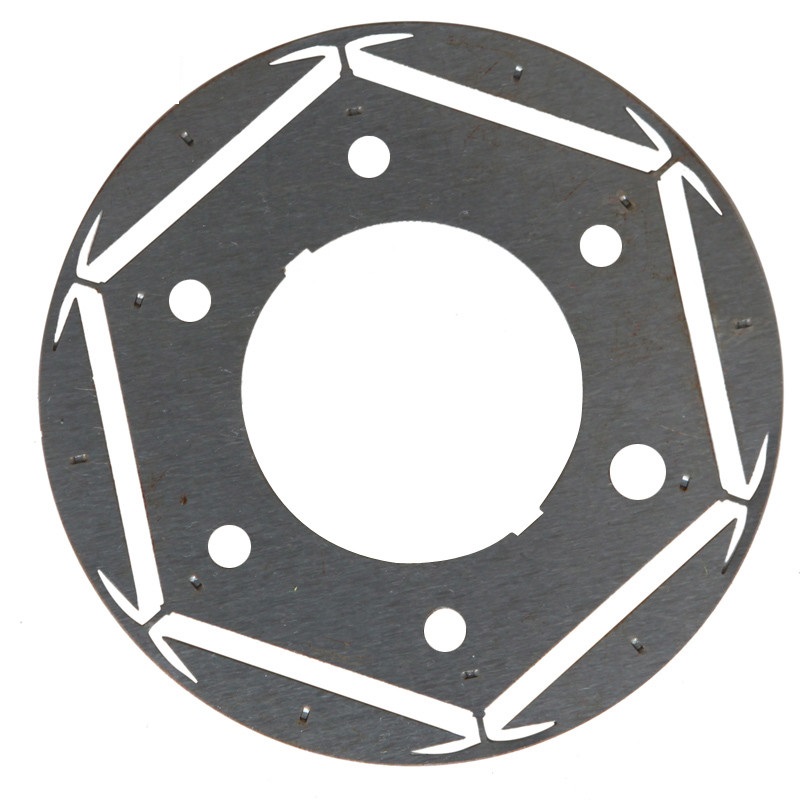

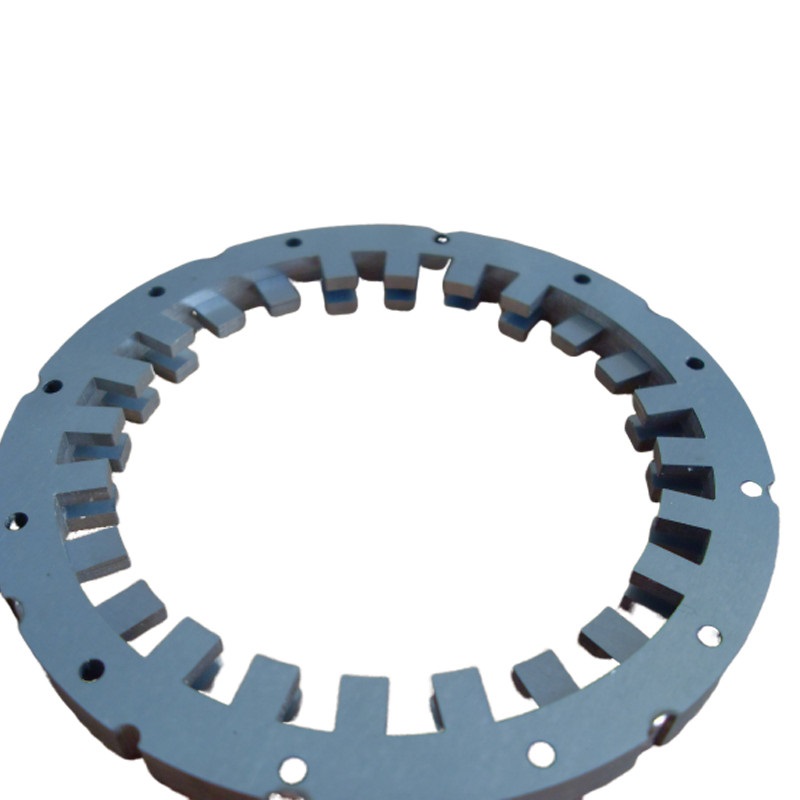

Servo Motor Rotor Lamination

Size:stator range 15~180mm

High-precision molds and elbow-type punching automatic production lines are used to complete the stamping manufacturing of various types of servo motor products, which provides greater accuracy and efficiency of iron core products.

Double-row, four-row, six-row and other rows of stamping are used to make the raw materials, and the utilization rate of raw materials is greatly improved. The rotor core uses pre-blanking and large-turn stamping technology, which makes the thinner structure design of the magnetic isolation bridge possible.

ADVANTAGE

A.Introduced the advanced SCHULER Equipment & Technology from Germany,which let us in the industry leading lever now

B.Achieve batch production of 0.1mm thickness silicon steel and 0.03mm thickness non-alloy material stamping

C.The single slot press can stamp OD2000mm Max

Nanjing university of aeronautics and astronautics into a high speed maglev motor studio

Cooperate with domestic benchmarking enterprises to establish new industry standards

Cross-class industry standards to build benchmark enterprises