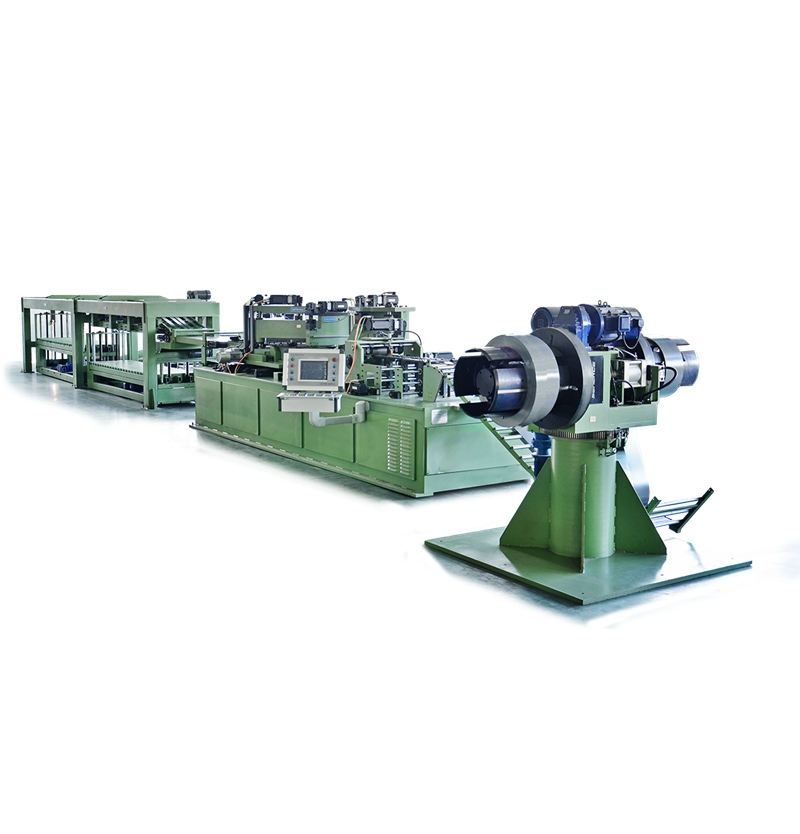

Silicon Steel CNC Automatic Transformer Core Lamination Servo Motor Cut to Length Line

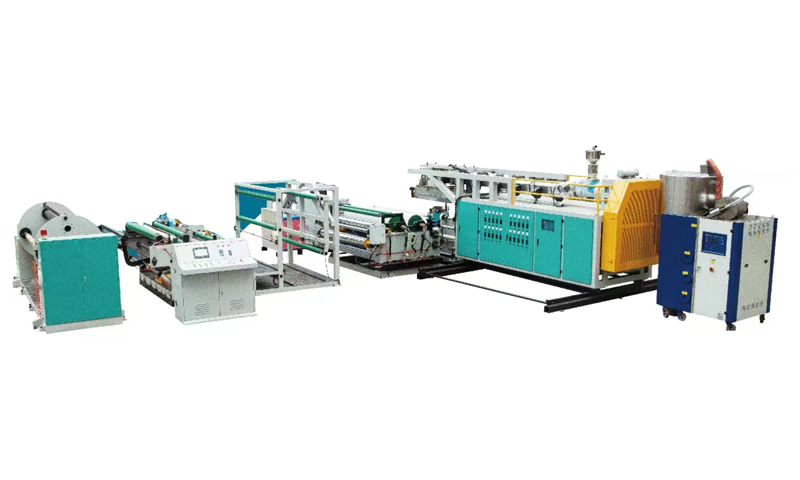

Reactor Disk Core Cutting Line

Composition of equipment

Double-head decoiler 1 set

Buffer unit 1 set

Sheet feeder 1 set

Punching unit (chamfer& U shape groove) 2 sets

Tape side giude 1 set

T type conjugate shearing device 1 set

Transmission and feed belt conveyor 2 sets

Automatic stacking machine 2 sets

Pneumatic system 1 set

Electric and CNC control system 1 set

Technical specification 1 set

Main Parameters

1) Raw material to be processed on this machine

Material : Silicon Steel

Material Tolerance :±0.1mm;

Material Burrs : ≤0.03mm

Material S Level : 0.1mm≤ 1000mm

Material Wave Level : ≤15 mm /1000mm

2)Process rangeMaterial Thickness : 0.18~0.35mm;

Material Width : 100~600mm;

Height of Core(H1):60~400mm;

Step-lap(W1,W2):W1+W2=W;

Minimum W1=12mm;Max: W2=600

Stepped size:0-600mm (customized)

U slot punch:W:25~40mm Depth:0~800mm

3) Processing Accuracy

Length Tolerance:±0.02mm/200mm;

Angle Tolerance:±0.005°;

Shearing Burr:≤0.02mm(1 million shearing /Grinding);

Punching Burr: ≤0.02mm(200 thousand punching /Grinding);

4) Feeding Speed:

Max feeding speed: 200m/min;

Effective Working Speed: 120m/min(related with quality of raw material and shape

of cutting);

5) Cutting Speed

25*2=50pc/min (Related to shape of the lamination)

6) Height of working table 1000mm

7) Outline dimension (max) 5600*5400*1900

8) Capacity 30KVA

9) Power AC380V±10%(3-phase),50Hz±2%

AC230V±10%(1-phase),50Hz±2%

10)Compressed air pressure 0.4~0.7MPa

Air consumption 0.5m³/min

11) Temperature 5-40℃ Air condition in control cabinet

12) Equipment working noise ≤65dB

13) Color: customized

Write your message here and send it to us