Silicone and Rubber Fabrication

Silicone Rubber

Silicone Rubber is an elastomer,it is widely used in industry, Silicone rubber is generally non-reactive, stable, and resistant to extreme environments and temperatures from −55 to 300 °C (−70 to 570 °F) while still maintaining its useful properties. Due to these properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including:voltage line insulators; automotive applications; cooking, baking, and food storage products; electronics ,medical devices and in home repair and hardware etc.

Liquid Silicone Rubber Injection Moldin

Silicone rubbers are widely used in industry, Silicone rubber is generally non-reactive, stable, and resistant to extreme environments and temperatures from −55 to 300 °C (−70 to 570 °F) while still maintaining its useful properties. Due to these properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including:

- Electronics and medical devices ;

- Voltage line insulators;

- Automotive applications;

- Cooking, baking, and food storage products;

Advantage

- Less scrap

- Less remaining flash on parting line

- Shorter LSR molding cycle time that can be measured in seconds as opposed to minutes for plastics.

- Preventing contamination from the environment by premixing LSR in a closed system.

- Molding smaller, complex and tight tolerance parts: by flow properties of LSR

- Ability to over-mold LSR onto thermoplastic, metal, magnesium, PCB, FPC and other materials

Silicone Rubber Compression Molding

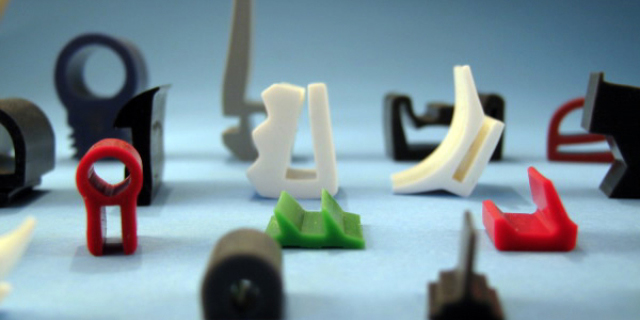

With more than 15 years of experience,Xiamen Ruicheng has the expertise necessary for providing an outstanding silicone rubber compression molding service. We offer small-volume silicone rubber compression molding products, including keypads, gaskets, key fobs, decorated plastic parts and more. We have successfully served customers in a variety of industries, including automobile, consumer electronics, household appliances, medical and more.

Advantage of Compression Molding

- Compared to the liquid injection molding, the mold development time for compression molding is shorter ,which is ideal for small-volume runs

- Delivers a faster production update period

- 3.Lower-cost production