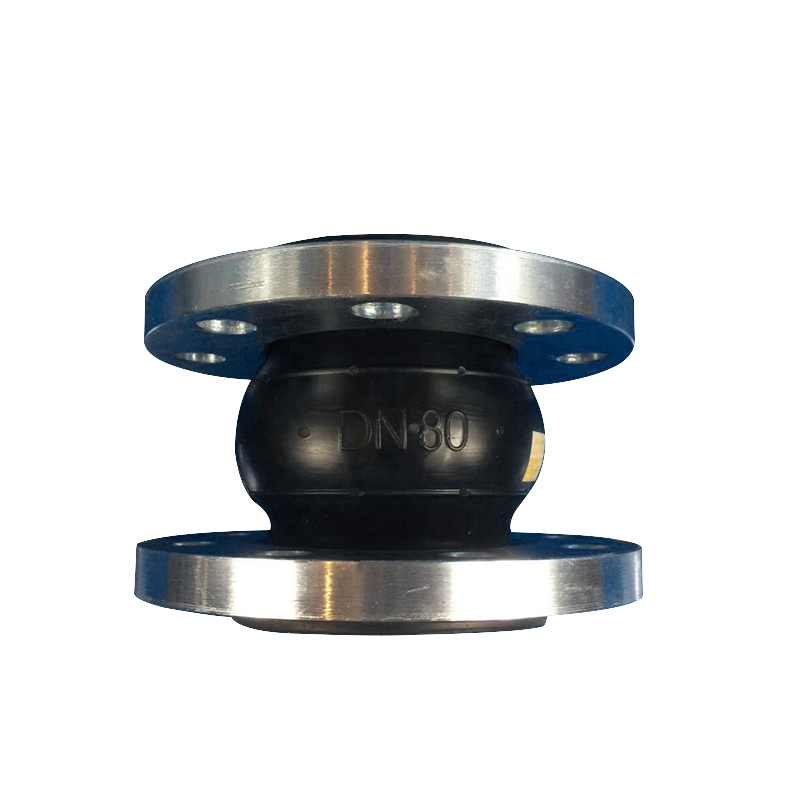

Single ball rubber soft joint

Key data

Product Introduction

Advantages/functions: shock absorption, noise reduction, protection of core components such as chiller, mechanical motor and other long-term use, does not transmit vibration to the pipeline, plays a role in protecting the pipeline and reduces maintenance costs; Solve the problem of flanges not parallel and pipes with different hearts.

Rubber material: NR,EPDM,NBR,PTFE,FKM (different materials according to different media, see the table for details).

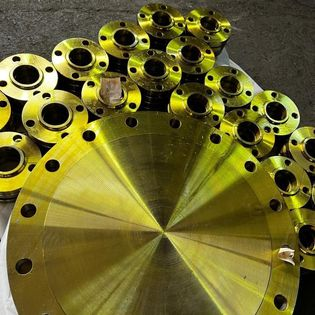

Flange material: ductile iron, malleable steel, carbon steel, stainless steel, PVC, etc.

The composition of rubber soft joint and the material used:

Also known as expansion joints or flexible connectors, rubber joints are used in a variety of industries including plumbing, HVAC (heating, ventilation, and air conditioning), and chemical processing. They are designed to absorb pipe movement and vibrations caused by temperature changes, pressure fluctuations and mechanical movements.

The joint’s inner rubber layer provides flexibility and elasticity, allowing it to absorb movement and vibration. The fabric reinforcement adds strength and stability to the joint, making sure it can withstand the pressure and stress imposed on the pipe. Middle and outer rubber layers provide extra protection and sealing. A reinforced metal or wire loop at the end of the fitting adds rigidity and helps hold the fitting in place. It is vulcanized with the rubber layer through a high temperature and high pressure process to ensure a strong and durable bond.

Rubber joints can be connected to pipes with metal flanges or loose sleeves of parallel joints. This allows for easy installation and removal when maintenance or repairs are required. The choice of joint rubber material depends on the specific application and the type of media it is in contact with. Different rubber materials have different properties and resistance.

For example, natural rubber has excellent elasticity and high tear strength. Styrene Butadiene Rubber (SBR) is commonly used for general purpose applications. Butyl rubber has excellent gas and chemical resistance. Nitrile rubber is known for its oil and fuel resistance. EPDM (etlene propylene diene rubber) has excellent weather resistance and ozone resistance. Neoprene is ozone, weather and abrasion resistant. Silicone rubber can withstand high temperatures, making it ideal for food and pharmaceutical applications. Viton has excellent heat resistance, chemical resistance and fuel resistance.

Overall, rubber joints play a vital role in maintaining the integrity and functionality of piping by reducing stress, absorbing motion, and compensating for temperature changes. With a variety of rubber material options, they are resistant to a wide variety of corrosive and harsh environments.