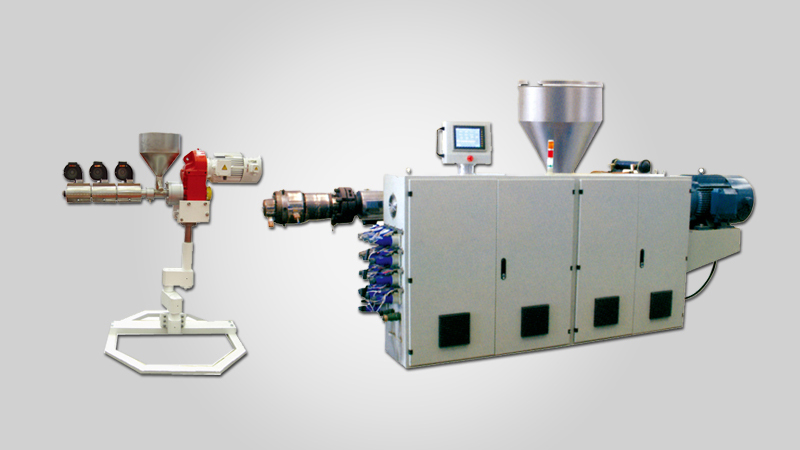

SJ Series Single Screw Extruder

Design Concept

1.High speed extruding based on high quality

2.Medium & low temperature plasticity concept guarantees the high quality of product extruding.

3.High hardness and degree of finish, low noise.

4.PLC intelligent control, convenient connection with assistant machine.

5.Strict temperature control system combines wind and water cooling together.

6.Comprehensive mixing design guarantees the mixing effect.

7.Supper pushing force bearing provides a high toque output.

Basic Structure

Single screw extuder is composed by pressing system, transmitting system and heating system.

Product Features

1.Hard face gear box; DC or AC CVT speed adjusting.

2.New type screw structure makes melt and mixing even and guarantee high production capacity with low melting temperature.

3.Cast copper or aluminum heater; wind or water cooling according to different requirements.

4.Barrel is made of special material and can be nitriding treated.

5.Advanced electric control system.

Advantages And Disadvantages

Advantages: Low price with simple design, wide application

Disadvantages:

1.The material transmission of single screw extruder rely on abrasion and this limits the material feeding performance, powder, mus material, glass fiber and inorganic material is difficult to feed.

2.When the die head pressure gets high the contra-flow appears lowering producing efficiency.

3.The gas drainage effect of single screw extruder is not good.

4.Single screw extruder is not applicable to some producing procedure for example thermal setting material processing.

Main Technical Parameters

| Model | (L/D) | Output(kg/h) | Speed(r/min) | Driving power(kw) | Center Height(mm) |

| SJ-25 | 25/1 | 5 | 20-120 | 2.2 | 1000 |

| SJ-30 | 25/1 | 10 | 20-180 | 5.5 | 1000 |

| SJ-45 | 25-33/1 | 50-150 | 20-150 | 7.5-22 | 1000 |

| SJ-65 | 25-33/1 | 60-250 | 20-150 | 15-90 | 1000 |

| SJ-75 | 25-33/1 | 100-350 | 20-150 | 22-110 | 1100 |

| SJ-90 | 25-33/1 | 180-550 | 20-110 | 30-185 | 1000-1100 |

| SJ-120 | 25-33/1 | 320-800 | 20-90 | 55-280 | 1000-1250 |

| SJ-150 | 25-33/1 | 400-1200 | 20-75 | 90-355 | 1000-1300 |