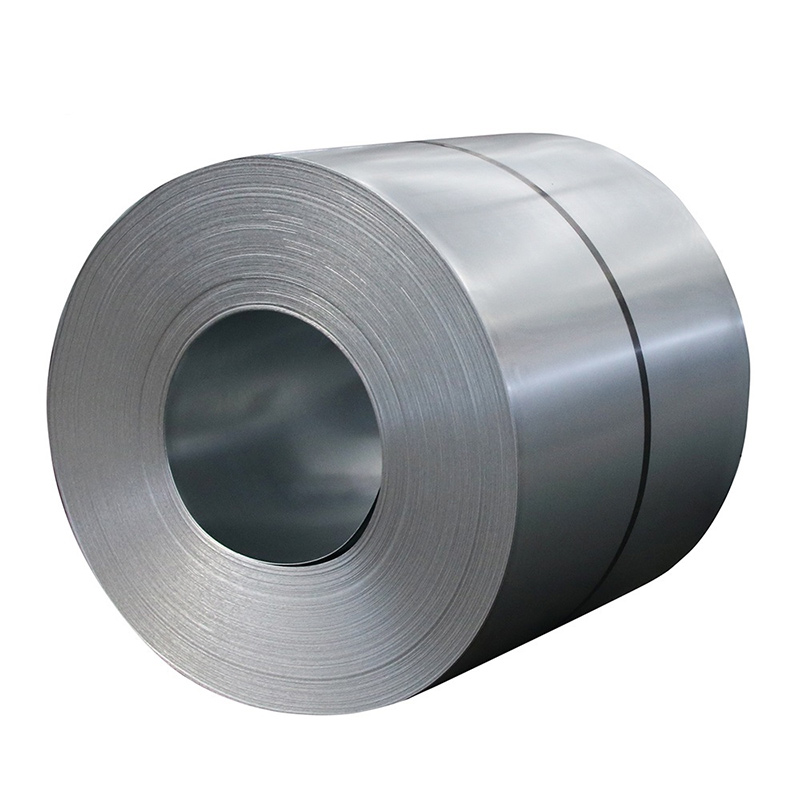

SPCC CRC cold rolled steel coil

1.Standard: AISI, ASTM, BS, DIN, GB, JIS

2.Grade: SPCC, DC01, DC02, DC03, DC04, ST12, ST13, ST14, ST15, SPCD, SPCE

3.Width: 1219mm

4.Thickness: 0.4mm, 1mm, 1.5mm, etc.

5.Coil ID: 508mm/610mm or as per customer’s requirement

6.Coil weight: from 6-15MT, according to the customer’s request

7.Surface treatment: Chemical passivating, oils, passivating + oils

8.Packing: standard sea-worthy packing

9.Appliction: Furniture pipe making

Technical Parameters

|

Classification |

Designation |

Size(mm) |

Main applications |

Characteristics |

|

Commercial quality |

SPCC |

Thickness :0.18-3.0 |

Refrigerators |

Commercial quality suitable for bending fabrication and simple forming; this is the type in greatest demand. |

|

Drawing quality |

SPCD |

Thickness :0.18-2.0 |

Automobile floor and roof |

Drawing quality second only that of SPCEN. Excellent uniformity. |

|

Deep-drawing quality |

SPCE |

Thickness :0.18-2.0 |

Automobile fenders and |

Deep-drawing quality. With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. |

|

SPCF |

Production process

No heating is carried out in the production process, so there are no defects such as pitting and scale which often occur in hot rolling, and the surface quality is good and the smoothness is high. Moreover, the dimension precision of cold-rolled products is high, and the properties and microstructure of the products can meet some special application requirements, such as electromagnetic properties and deep drawing properties.

Feature

Low carbon steel is mainly used, which requires good cold bending and welding performance, as well as certain stamping performance.

Application

Cold rolled steel coils are widely used, such as automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, canned food and so on.

DC01, DC02, DC03, DC04, SPCC, SPCD, SPCE grades are usually used for parts formed by deep drawing with general forming knives.