Special Material Hydrogenation Tube for High-Pressure Hydrogen Pipeline

Advanced Materials Technology

Our specialty material hydrogenation tubing is precision engineered from cutting-edge materials for exceptional strength, durability and ability to withstand extreme operating conditions. The use of these specialty materials ensures enhanced compatibility with high-pressure hydrogen, reducing the risk of leaks or potential hazards, while improving the overall performance of the operation.

Unparalleled Quality

Our special material hydrogenation tubes go through a rigorous testing and inspection process and comply with international industry standards. Thanks to our stringent quality control measures, our pipelines guarantee long-lasting performance, minimizing downtime and maintenance costs for hydrogenation pipelines.

Enhanced Security Features

Safety is paramount in any hydrogenation operation. With special material hydrogenation tubes, we have integrated a range of state-of-the-art safety features for your peace of mind. Our tubing has high resistance to hydrogen embrittlement and corrosion, protecting your operation from potential failures or accidents. Investing in our products means investing in the safety of your team.

Improve Efficiency

In addition to safety and quality, our special material hydrogenation tubes can also improve the overall efficiency of the hydrogenation process. The advanced materials used in its structure have better thermal conductivity, which improves heat transfer and increases reaction rates. This means shorter processing times, higher productivity and ultimately, higher profitability for your business.

Custom Made

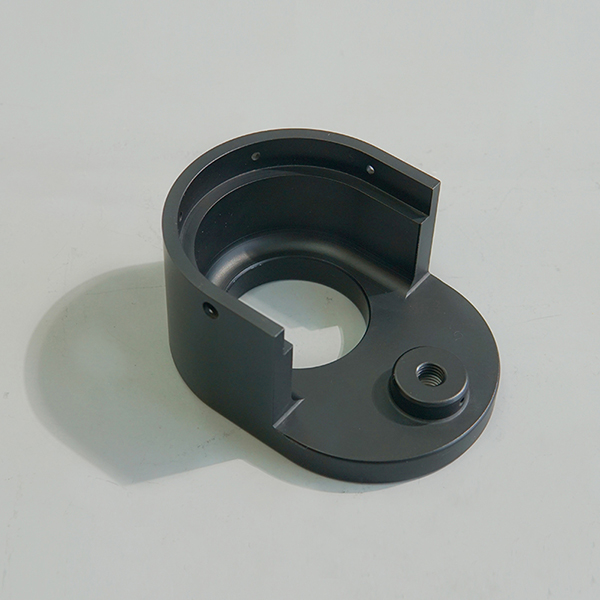

We understand that every business buyer has unique needs. That’s why we offer custom options for specialty material hydrogenation tubing. Whether it’s a specific size, shape or surface finish, our experts work closely with you to customize the product to your exact specifications, ensuring seamless integration into your existing hydrogenation system.

Product Advantages

1. The hydrogenation tube is made of high nickel equivalent material (nickel equivalent ≥ 32%), which has better resistance to hydrogen embrittlement than conventional materials.

2. The yield and tensile strength of the hydrogenation pipe is 50% higher than that of ordinary materials, and it has stronger compressive capacity. Under the same working pressure, the wall thickness of the steel pipe is thinner, and the internal flow of the steel pipe is large, which realizes rapid filling and increases work efficiency.

3. The hydrogenation pipe can be connected by automatic welding instead of threaded connection, which reduces the risk of leakage and increases the safety factor.