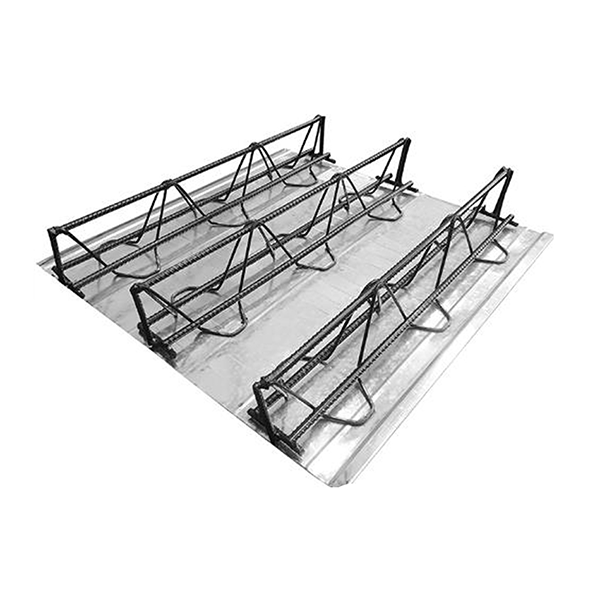

Steel Truss Deck For Construction

Specifications

1)Material:

Upper rebar and lower rebar: HRB400E, CRB550

web rebar: Cold rolled bright steel round bars

Bottom membrane plate: According to different applications, galvanized steel sheet or cold rolled steel sheet can be used, the thickness is usually 0.5-0.6mm, and the zinc layer is 120g on both sides.

2)Packing: standard sea-worthy packing

3)Surface treatment: galvanized

4)Size: as per customer’s requirement

| The diameter of upper rebar | 6-12mm | |

| The diameter of lower rebar | 6-12mm | |

| The diameter of web rebar | 4-6mm | |

| The height of the truss | 70-270mm | |

| The diameter of the horizontal support rebar | 8, 10mm | |

| The diameter of the Vertical support rebar | HPB235 | 12(for h≤150); 14(for h>150) |

| HRB335, HRB400 | 10(for h≤150); 12(for h>150) | |

Application

The applicable scope of steel truss deck is applicable to both steel structure and concrete structure. First of all, because of the large amount of steel bars, the steel truss bears a large unsupported span. Therefore, for buildings with a span of more than 4.5 meters, it is beneficial to choose the steel truss deck, because it can make a large unsupported span. Thirdly, because there are many steel bars, which can bear great late load, the steel truss deck is more suitable for buildings with late load capacity above 1.5 tons. Also, it is quite suitable for industrial plants with low floors. This can avoid the drawback that steel truss floor slabs occupy a large number of cranes in high-rise buildings.

Advantage

Steel deck realizes mechanized production, which is beneficial to uniform arrangement and spacing of steel rebar and uniform thickness of concrete protective layer, and improves the construction quality of steel truss deck. Assembled steel truss deck can significantly reduce the amount of steel binding on site, speed up the construction progress, increase the construction safety guarantee and realize civilized construction. Assembled templates and connectors are convenient to disassemble and assemble, can be reused for many times, saves steel, and meets the requirements of energy conservation and environmental protection. But also greatly improves the labor productivity and effectively reduces the product cost.