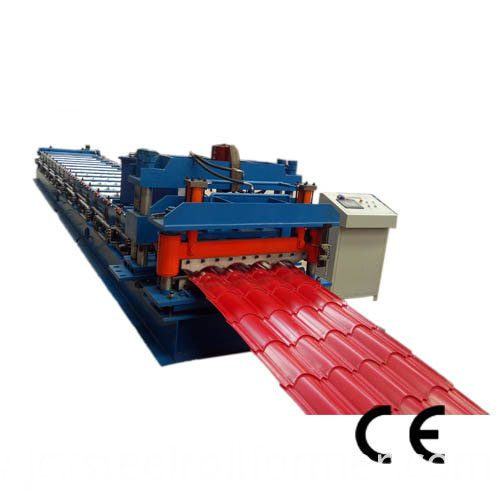

Step tile roll forming machine

Basic Info

Model No.: 1100 step tile

Additional Info

Productivity: 25sets/Month

Place of Origin: China

Supply Ability: 25sets/Month

Product Description

Step tile Roll Forming Machine

Metal step roof tiles produced by glazed tile roll forming machine from high quality prepainted sheets most time apply as roofing on Villas or some residential buildings.

There is only one but key difference between a metal glazed roof tile and a regular metal roof panel: Steps! Generally speaking, a regular metal roof panel with steps is called a metal glazed roof tile.

1.Main parameters of step tile :

Parameters of raw material

| Material | Thickness | I.D | Yield Strength |

| Q235 gi&ppgi& galvalume |

0.25-0.7mm | 508mm | <=235mpa |

Decoiling → Roll Forming →Hydraulic cutting→Collecting table

2.Photos of Machine:

68991d7c612bc495805cafc1c9.jpg” width=”700″ height=”566″ title=”Roll Forming Machine” alt=”Roll Forming Machine” />

3.Technology parameters:

The weight of machine is about3.1tons.The total dimension of machine:6800(L)*1200(W)*1500mm(H)

3.1Manual decoiler:

Capacity of uncoiler:5tons

Expansion of segment:Manual

Rotation of segment:Manual

Number of segment:4

Range of segment expansion:480-520mm

Operation method:Manual

Qty: 1

3.2 Guiding system:

To keep the material straight

Entrance and adjustable wheel: 2rolls

Qty: 1

3.3Main forming machine:

Coil thickness:0.25-0.7mm

motor type: 3 phase asynchronous motor

Main motor power:4kw+3kw(normal speed),

Approx.13groups roller including

Roller : S45C with quenching treatment,Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

Shaft:Diameter of max shaft: ø70mm(hardening and tempering)

Transmission type:by one inch chain

Qty: 1

3.4 Hydraulic cutting:

Material of blade: Cr12Mov,HRC58-62

Length measuring: Automatic encoder length measuring

Type of cutting:Cutting after forming:Cut the sheet after roll forming to required length.No need to change mold for different sizes

Cutting motion:The main machine automatically stops and the cutting will take place.After the cutting,the main machine will automatically start.

Power of motor:3kw

3.5 Product support frame

Size: L 3m x W0.5m

Looking for ideal Step Tile Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Africa Step Tile Forming Machine are quality guaranteed. We are China Origin Factory of Africa Roof Cold Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Roof And Wall Panel Roll Forming Machine > Roof Tile Roll Forming Machine