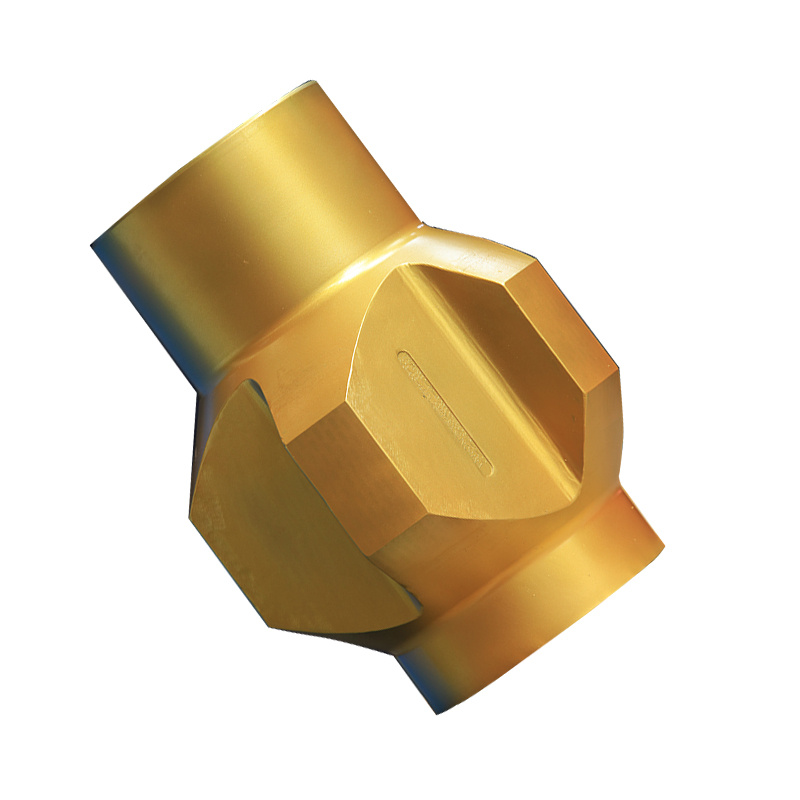

Straight or Spiral Blade Motor Stabilizer

Straight or spiral blade motor stabilizer advantage of WELONG

• Motor Stabilizer is customized, Motor stabilizer forging and final stabilizer are available from us.

• Both of Motor Stabilizer size and shape are customized.

• Material steel mill is audited per biennium and approved from our company WELONG.

• Each stabilizer has 5 times nondestructive examination (NDE).

• Motor stabilizer are exported to countries such as the United States, Dubai, Saudi Arabia, etc.

Motor stabilizer Main Material

AISI 4145H MOD, 4330, 4130, 4340, 4140 and etc.

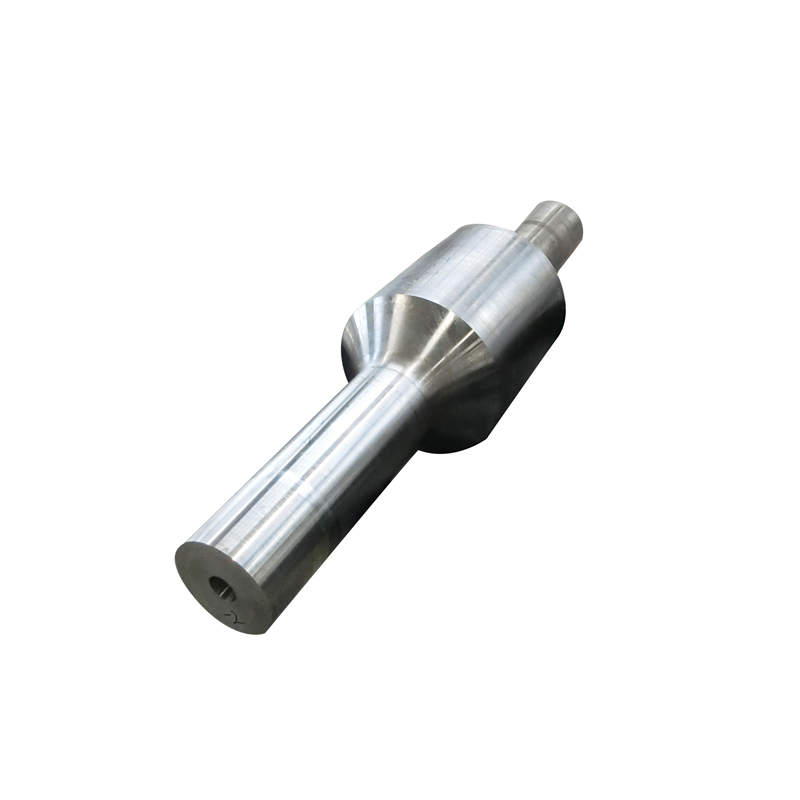

Motor stabilizer Process

Forging + Rough machining + Heat Treatment +Property Self-Testing + The third-party testing + Finishing Machining + hard facing welding +painting+ Final inspection + Packing.

Motor stabilizer dimension

Manufacturing diameter range is from 5”to 40”.

Motor stabilizer future

• Removability: The interchangeable motor stabilizer designed as a detachable and replaceable component, making it easy to install and disassemble when needed. This makes maintenance and repair work more convenient and reduces downtime.

• Adjustment ability: The motor stabilizer has certain adjustable functions, which can adapt to different wellhead conditions and pipeline sizes. They usually have adjustable threads or other mechanisms to ensure correct alignment and fixation.

• Corrosion resistance: The environment in the petroleum industry often has characteristics such as high temperature, high pressure, and corrosive media. motor stabilizer are usually made of corrosion-resistant materials, such as alloy steel or stainless steel, to ensure their long-term use under harsh conditions.

• High strength and wear resistance: Due to the presence of high pressure and strong friction in the petroleum industry, motor stabilizer typically require high strength and wear resistance. They may use special heat treatment processes to enhance their strength and durability.

• Safety: The application of interchangeable motor stabilizer in the petroleum industry often involves high-risk environments. Therefore, its design and manufacturing must comply with strict safety standards to ensure personal safety and equipment integrity during the work process.

Application of Straight or spiral blade motor stabilizer

• Drilling: motor stabilizer can be used for directional control and wellbore trajectory correction during the drilling process. They can be installed on the drill pipe assembly, adjusting the position and direction of the drilling tool to drill the wellbore according to the design requirements.

• Wellbore repair: during the wellbore integrity repair process, the motor stabilizer can be used to restore the verticality, flatness, and diameter of the wellbore. They can ensure that the repaired wellbore meets the specified standards by measuring and adjusting the position and shape of the inner wall of the wellbore.

• Oil well production: The stabilizer can also be used for alignment and adjustment during the oil well production process. They can be used to correct and calibrate the position of wellhead equipment, pipelines, and valves to ensure smooth and efficient production operations.

• Pipeline installation and maintenance: During the installation and maintenance process of oil pipelines, stabilizer can be used to adjust and align the position and direction of pipelines. This helps to ensure correct connection, good operation, and optimal fluid transmission of pipelines.

• Tanks and containers: stabilizer is also used in the installation and maintenance of petroleum tanks and containers. They can be used to adjust and calibrate the flatness, roundness, and alignment with other components of the tank wall.

The application of stabilizer in the petroleum industry aims to improve production efficiency, ensure correct alignment of equipment and structures, and minimize deviations that may cause accidents or quality issues. By using stabilizers, the petroleum industry can ensure the accuracy and consistency of various processes, thereby enhancing the safety and reliability of operations.