Swiss Machining

Where is Swiss Machining Used?

Swiss machining can produce small, intricate parts in high-volume for a number of industries, predominantly automotive, medical, defense, and electronics-related sectors. Swiss Machined PartsCNC Swiss-style machining has the capability to machine longer, slender, and more complex parts with incredible accuracy, efficiency, and throughput.

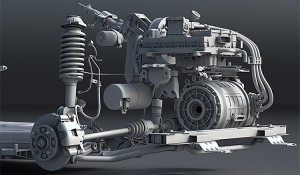

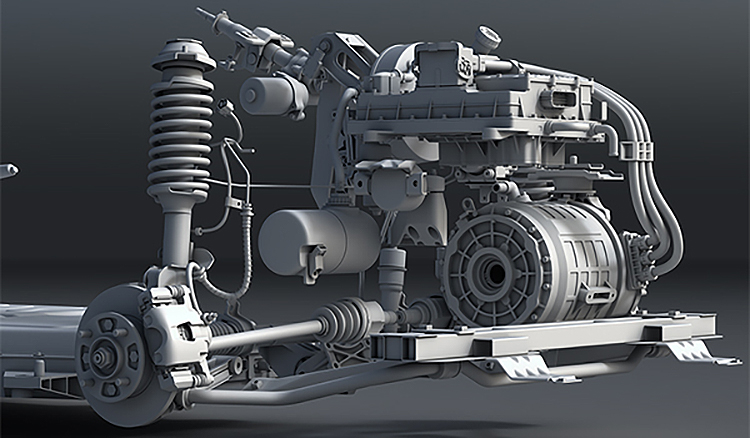

Automotive

CNC machining services are used to manufacture precise components for vehicles, such as engine parts and chassis components.

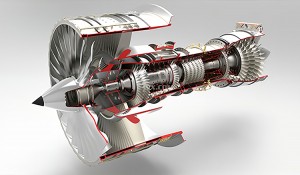

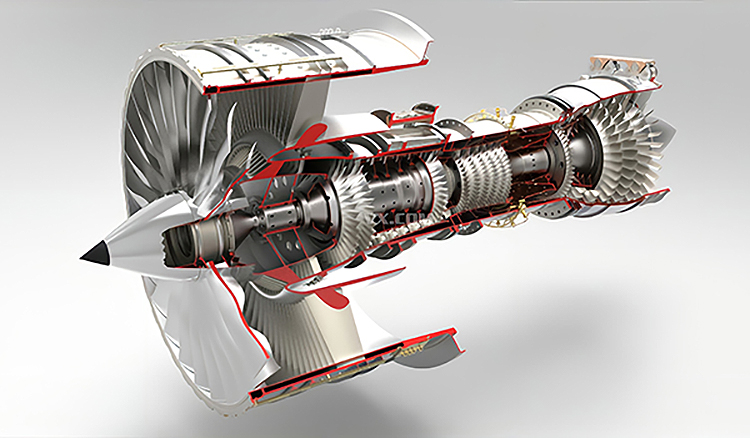

Aerospace

CNC machining services produce complex and critical components for the aerospace industry, including turbine blades and aircraft structural parts.

Consumer Goods

CNC machining services manufacture a wide range of consumer products with precise dimensions and high-quality finishes.

Medical Devices

CNC machining services produce intricate and accurate components for medical devices, such as surgical instruments and implants.

Electronics

CNC machining services produce precise components for electronics, such as circuit boards and connectors, with excellent electrical conductivity.

Swiss Lathe Capabilities

From small runs of a few hundred pieces up to hundreds of thousands, Swiss CNC machining allows designers to manufacture complex components on one machine. High-volume production runs with this machining can cover numerous processes, including, milling, threading, drilling, boring, turning, and other custom requirements. One machine can perform several operations at once in a shorter period of time while offering designers more control in the production of complex parts.

Swiss CNC machining can produce complex stainless steel parts from 0.030″ to 2″ in diameter parts. This allows designers to meet the unique specifications of even the most demanding applications.

Other metals, such as inconel, titanium, nickel and nickel-based alloys, can also be used to produce parts that require tight tolerances of ±0.0005 concentricity within 0.0001 inches.

Swiss machining allows micromachining of tiny parts that are more accurate, smaller and lighter – and faster. All of this allows Swiss machines to perform more complex machining operations than any other type of CNC machining system.