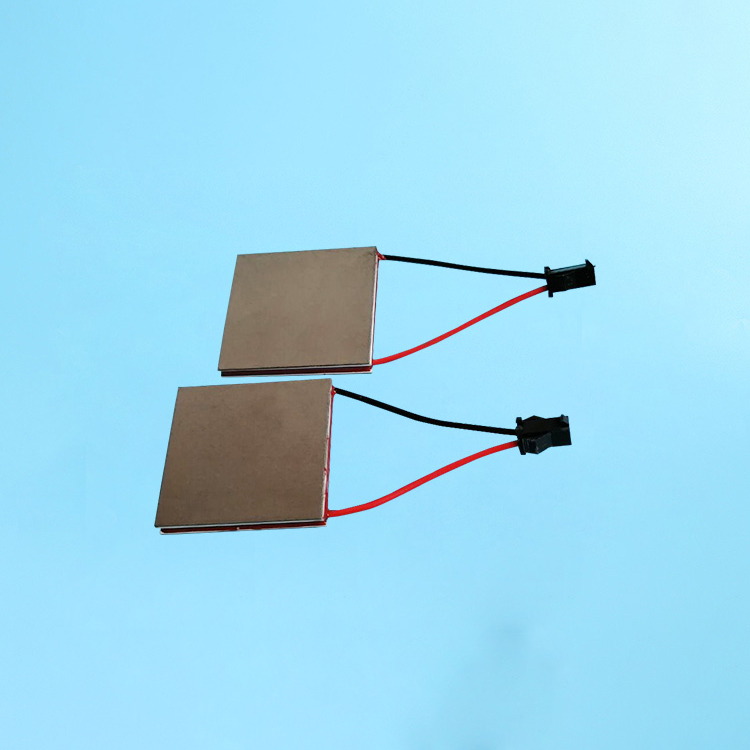

TEG thermoelectric generator series

“Thermo generation module” is able to generate electrical power from any type of temperature difference from micro-power wireless monitoring to large-scale waste heat recovery.

is providing various thermo generation modules to fit your application needs.The Max temperature can be 280℃. Customized size is available.

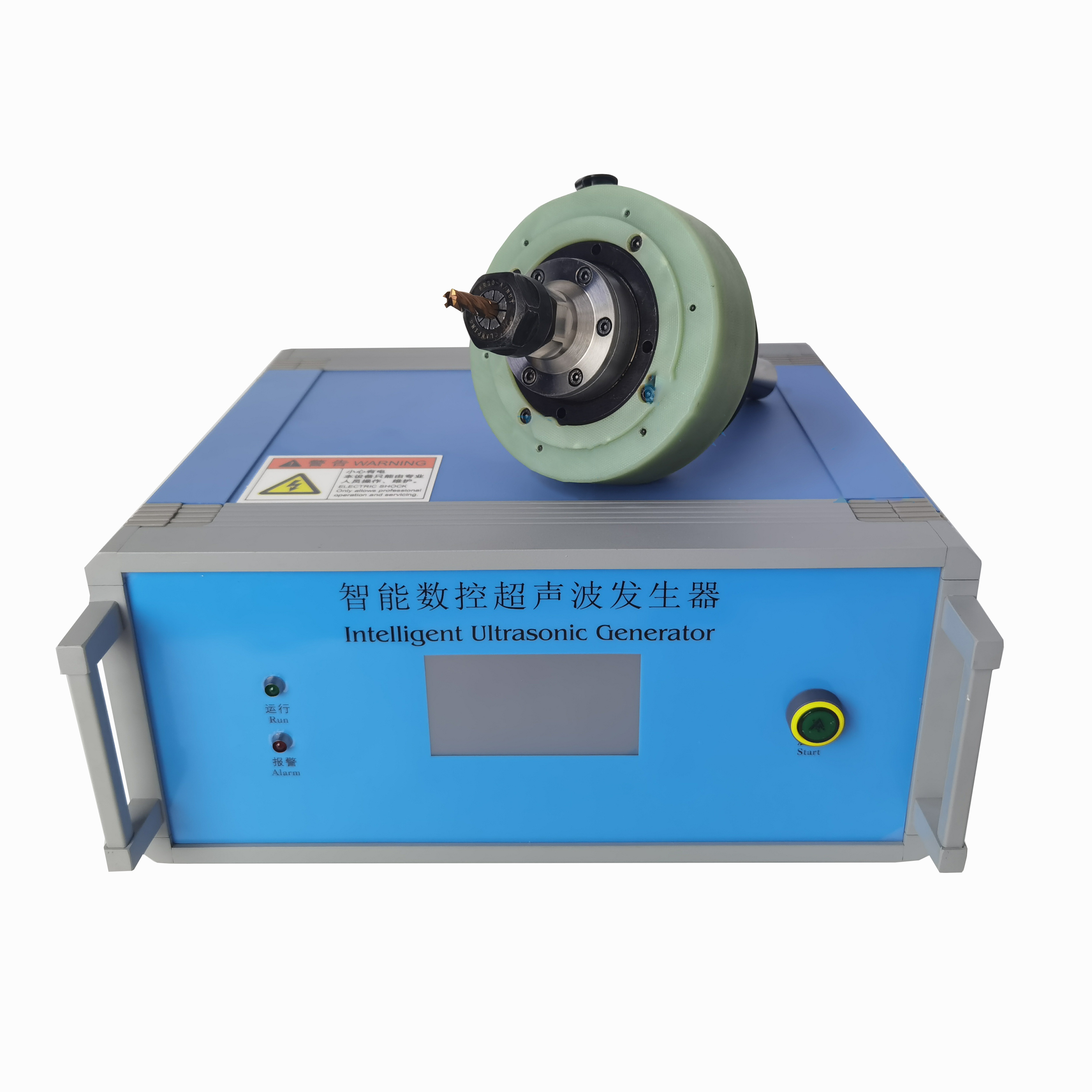

MACHINE

WORKSHOP

WORKSHOP

*Our advantages

Relying on professional technical team and laboratory in Shenzhen, we provide the best solutions of thermoelectric module use. Each piece of our module is tested 3 times under advanced equipments. The reject ratio of our modules is under less than five in then thousand. Our products widely applied in medical equipment, optical communication, aerospace, automotive etc. We also have professional technical team which is focusing on expanding new application of thermoelectric modules. So your requirements can be satisfied properly.

*Heat dissipation mode

The heat dissipation of semiconductor cooling fins is a professional technology, and it is also the basis for the long-term operation of semiconductor cooling fins. Good heat dissipation is a prerequisite for obtaining low cold end temperature. The following are several heat dissipation methods of semiconductor cooling fins:

1. Natural heat dissipation:

It adopts materials with good thermal conductivity and red copper aluminum materials to make various heat sinks, which can freely dissipate heat in still air. It is easy to use. The disadvantage is that the volume is too large.

2. Liquid filled (water cooled) heat dissipation:

The water tank is made of better heat dissipation materials and cooled by means of liquid or water. The disadvantages are inconvenient water use and too much waste. The advantages are small volume and good heat dissipation effect.

3. Forced air cooling:

The working atmosphere is flowing air. The material of the heat sink is the same as that of the natural heat sink. It is convenient to use and the volume is smaller than that of the natural cooling. The disadvantage is that a fan is added to make noise.

4. Vacuum latent heat dissipation:

Commonly used is the “heat pipe” heat sink, which uses the latent heat of evaporation to quickly transfer heat capacity.

Special reminder: it is forbidden to power on the test without radiator, otherwise the refrigerant will be burned.