Titanium Aluminum

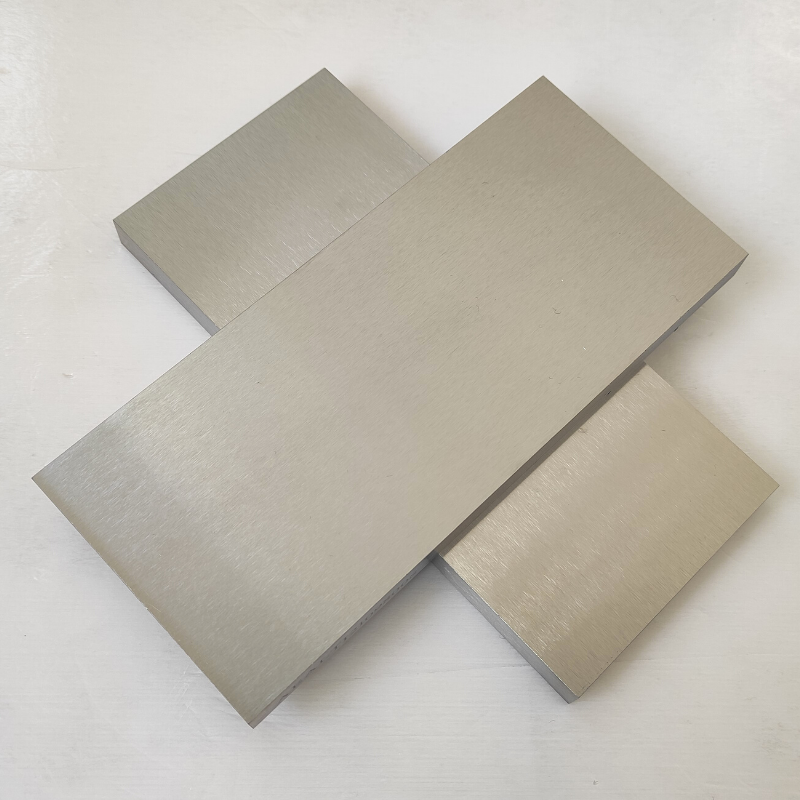

Titanium Aluminum Sputtering Target Description

The requirement of the target quality for sputter coating is higher than that of the traditional materials industry. The uniform microstructure of the target directly affects the sputtering performance. We have a completed quality management system and we select high purity raw materials and thoroughly blend them to ensure homogeneity. Titanium Aluminum alloy sputtering target is produced by means of vacuum hot pressing method.

Our Titanium Aluminum sputtering targets could provide an outstanding oxidation-resistant nitride coating, Titanium aluminum nitride (TiAlN). TiAlN is the current mainstream as a film for cutting tools, sliding parts and tribo-coatings. It has high hardness, toughness, wear resistant performance and oxidation temperature.

Our typical TiAl targets and their properties

|

Ti-75Al at% |

Ti-70Al at% |

Ti-67Al at% |

Ti-60Al at% |

Ti-50Al at% |

Ti-30Al at% |

Ti-20Al at% |

Ti-14Al at% |

|

|

Purity (%) |

99.7 |

99.7 |

99.7 |

99.7 |

99.8/99.9 |

99.9 |

99.9 |

99.9 |

|

Density(g/cm3) |

3.1 |

3.2 |

3.3 |

3.4 |

3.63/3.85 |

3.97 |

4.25 |

4.3 |

|

Grain Size(µm) |

100 |

100 |

100 |

100 |

100/- |

- |

- |

- |

|

Process |

HIP |

HIP |

HIP |

HIP |

HIP/VAR |

VAR |

VAR |

VAR |

Titanium Aluminum Sputtering Target Packaging

Our Titanium Aluminum sputter target is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Get Contact

RSM’s Titanium Aluminum sputtering targets are of ultra-high purity and uniform. They are available in various forms, purities, sizes, and prices.

We could supply a variety of geometric forms: tubes, arc cathodes, planar or custom-made, and wide proportion range of Aluminum. Our products feature excellent mechanical properties, homogeneous microstructure, polished surface with no segregation, pores, or cracks.

We specialize in producing high purity thin film coating materials with excellent performance as well as the highest possible density and smallest possible average grain sizes for use in mold coating、decoration、automobile parts、low-E glass、semi-conductor integrated circuit、thin film resistance、graphic display、aerospace、 magnetic recording、touch screen、thin film solar battery and other physical vapor deposition (PVD) applications. Please send us an inquiry for current pricing on sputtering targets and other deposition materials not listed.