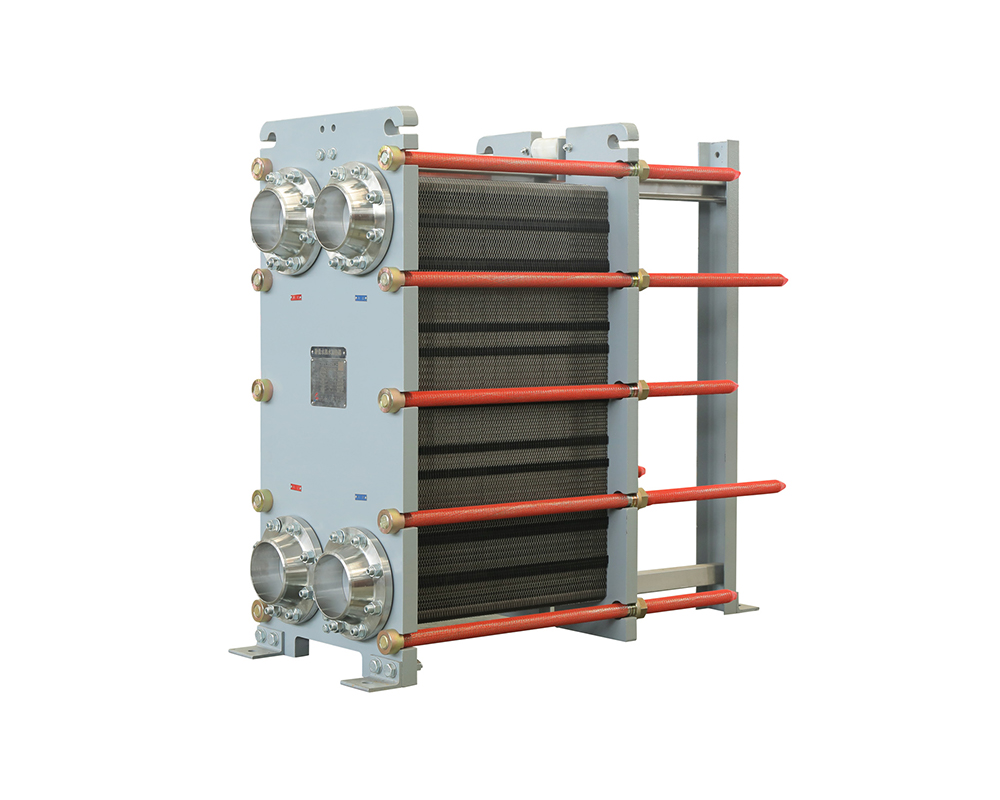

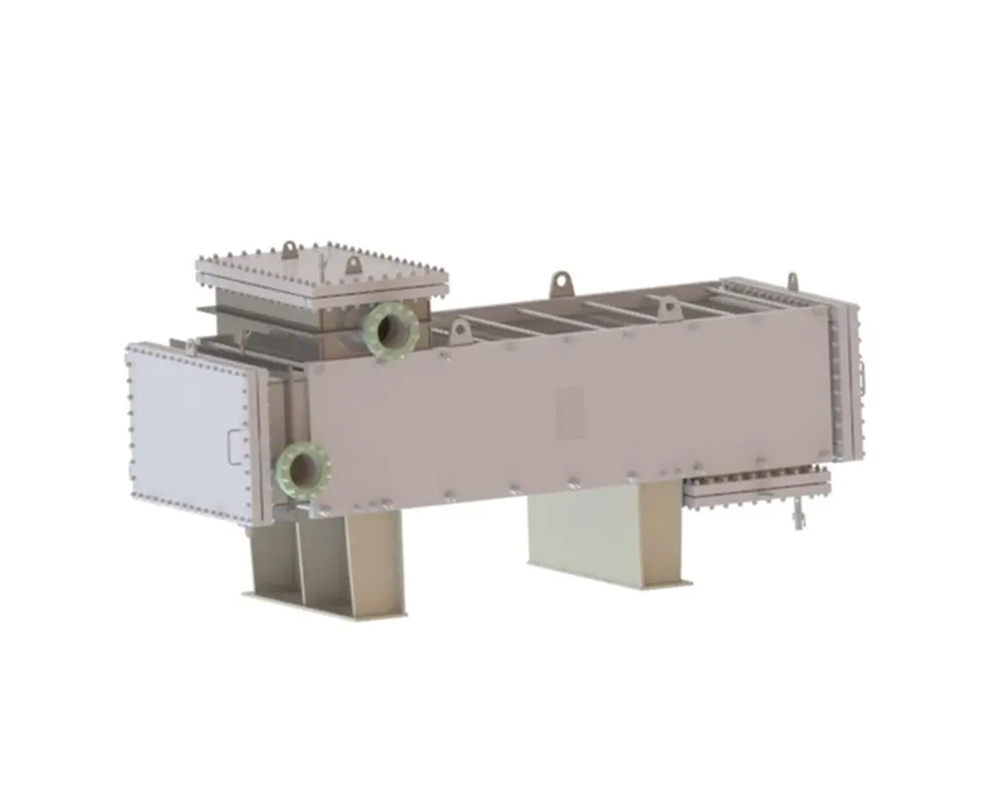

Titanium Plate & frame heat exchanger

Principle

Plate & frame heat exchanger is composed of heat transfer plates (corrugated metal plates) which are sealed by gaskets, tightened together by tie rods with locking nuts between frame plate. The port holes on the plate form a continuous flow path, the fluid runs into the path from inlet and is distributed into flow channel between heat transfer plates. The two fluids flows in counter current. Heat is transferred from hot side to cold side through heat transfer plates, the hot fluid is cooled down and the cold fluid is warmed up.

Parameters

| Item | Value |

| Design Pressure | < 3.6 MPa |

| Design Temp. | < 180 0 C |

| Surface/Plate | 0.032 - 2.2 m2 |

| Nozzle Size | DN 32 - DN 500 |

| Plate Thickness | 0.4 – 0.9 mm |

| Corrugation Depth | 2.5 – 4.0 mm |

Features

High heat transfer coefficient

Compact structure with less foot print

Convenient for maintenance and cleaning

Low fouling factor

Small end-approach temperature

Light weight

Material

| Plate material | Gasket material |

| Austenitic SS | EPDM |

| Duplex SS | NBR |

| Ti & Ti alloy | FKM |

| Ni & Ni alloy | PTFE cushion |