TQLZ-A(B) Vibrating Paddy Cleaner

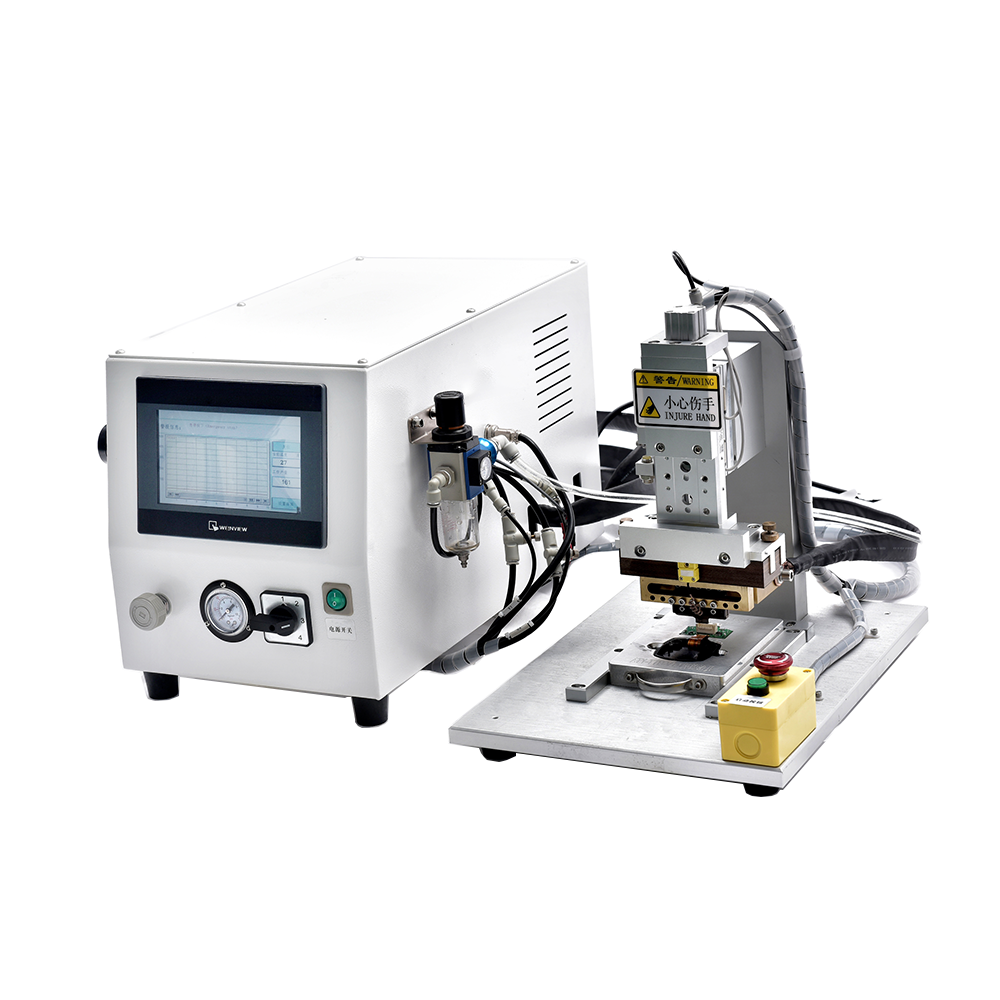

This equipment is motivated by vibration electromotor with compact structure, light vibration power and adjustable vibration directions and screen surfaces based on different needs. It is with nice appearance, stable operation, good sealed characteristic and ideal cleaning effect.

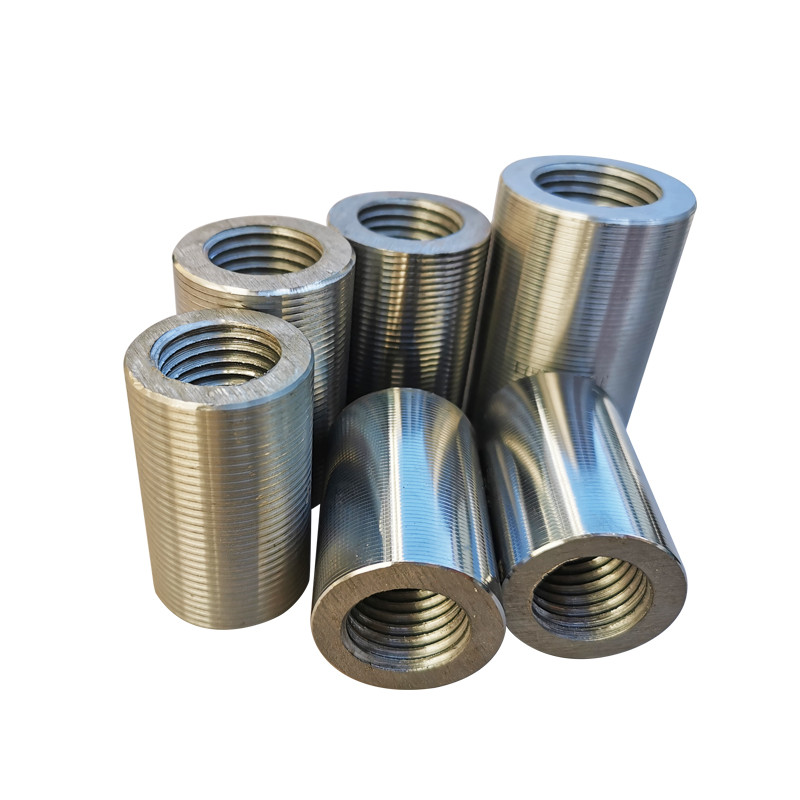

TQLZ vibration sieve cleaning materials are mainly based on different particle size, using different sieve sieve face materials selection, screen surface for punching sieve plate, a round hole, the long holes, such as hole triangular form, in accordance with raw materials different, the choice of different screen surface.

Material feed me through the door after the pressure, even fallen on the screen surface of the first layer, of the big screen impurities from the major export separating impurities, the screen fell on the second tier sieve surface of the sieve Material from the mouth into vertical suction duct into the wind-election, isolated in the light of miscellaneous materials, under the screen of a small impurities from the export of small miscellaneous.

| MODEL | CAPACITY |

POWER |

WEIGHT |

EXTERIOR SIZE |

| TQLZ100A/B | 5.0-6.0t/h |

0.37kw×2 |

700kg |

2750×1550×1650mm |

| TQLZ125A/B | 6.0-8.0t/h |

0.37kw×2 |

800kg |

2750×1780×1650mm |

| TQLZ150A/B | 9.0-14t/h |

0.56kw×2 |

900kg |

2750×2050×1650mm |

| TQLZ180A/B | 14-18t/h |

0.56kw×2 |

1100kg |

3000×2300×1650mm |

| TQLZ200A/B | 15-30t/h |

0.56kw×2 |

1200kg |

3000×2500×1650mm |