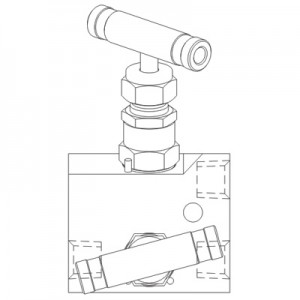

Tube Fittings-Union

Introduction

tube fittings are available in a variety of materials, including optimized 316 stainless steel chemistry with elevated nickel, chromium, and other elements for superior corrosionresistance in a variety of applications, including chemical processing, sour gas and subsea systems. continues to improve the performance and reliability of the tube fitting for use in thousands of diverse applications—including research, alternative fuels, analytical and process instrumentation, oil and gas, power, petrochemical, and semiconductor industries.

Features

Twin ferrule fittings provide metal-to-metal seal connections, non-elastomeric seals for leak-free connections twin ferrule fittings are designed to have a maximum allowable working pressure that is higher than that of any tubingIndustry standard design for all instrumentation grade tubingStainless steel tube harderness: the hardness of the tube shall be not greater than 85 HRBAvailable in sizes from 1/16 to 2in and 2 mm to 50 mm fittings materials include 316 stainless steel, steel, brass, aluminum, nickel-copper, Hastelloy C, 6Mo, Incoloy 625 and 825 special treated back ferrule is to provide secureSilver coated threads to reduce gallingLeak-proof joints capable of satisfying high pressure vacuum and vibration applications