Tungsten Carbide Bushing&Carbide Sleeve

Description

Making of tungsten carbide material, tungsten carbide bush shows high hardness and transverse rupture strength, and it has superior performance on resisting abrasion and corrosion, which enable it to be widely used in many industries.

Base on different application of the users, carbide sleeves are usually made of different tungsten carbide grades. The major two series of tungsten carbide grade is YG series and YN series. Generally speaking, YG series tungsten carbide bushing have higher transverse rupture strength, while YN series tungsten carbide bush resist corrosion better than the former one.

For its specific uses, tungsten carbide sleeves are often made with high accuracy, and owing to their perfect finish, precise dimension, durability and corrosion resistance, these are highly appreciated by the clients all around the world. And the followings are the finished tungsten carbide bush and blank ones.

In addition, differ from the various of application environment, there are several types of tungsten carbide bushes, such as tungsten carbide ferrules, tungsten carbide guide bushes and tungsten carbide drill bushes, etc. Most of the specifications are all customized, and China tungsten Online is backed by rich industry knowledge and production experience of various tungsten carbide bushes, thus can produce various of tungsten carbide bushes based on specific design.

Photos

tungsten carbide bush

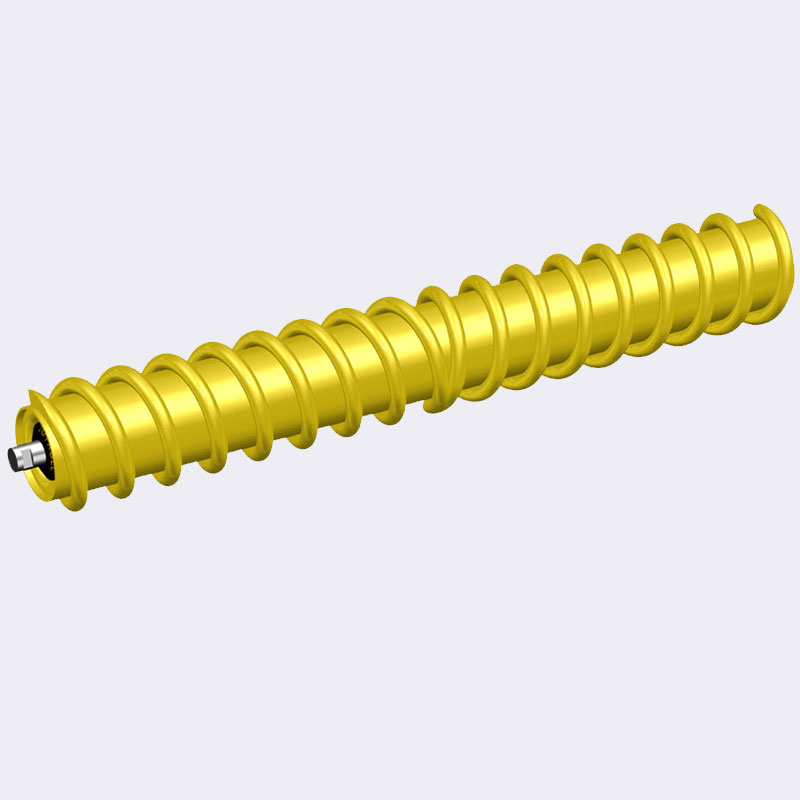

carbide sleeve with groove

tungsten carbide shaft sleeve