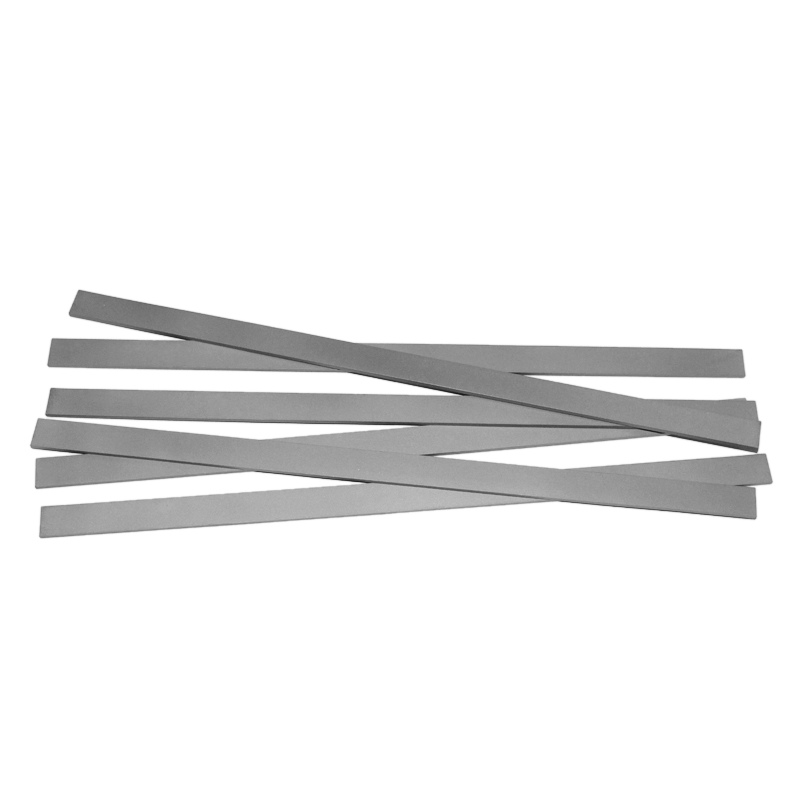

Tungsten carbide flat strips for woodcutting machine

Features

Cemented carbide strips have high hardness, good wear resistance, high elastic modulus, high compressive strength, good chemical stability (acid, alkali, high-temperature oxidation resistance), low impact toughness, low expansion coefficient.

Technological Process

Powder making → Formula according to usage requirements → Wet grinding → Mixing → Crushing → Drying → Sieving → Addition of forming agent → Re drying → Preparation of mixture after sieving → Granulation → Pressing → Forming → Low pressure sintering → Forming (blank) → Flaw detection inspection → Packaging → Warehousing

Advantages

1. Various Grades and dimensions with virgin material.

2. Fast Lead time with stable and good quality.

3. Customized size are acceptable

Grade recommend

Specification

| Type(T*W*L) | Tolerance of T(mm) | Tolerance of W(mm) | Tolerance of L(mm) |

| 1*(2-5)*L | T≤7.0T +0.2~+0.5

T>7.0 T +0.2~+0.6 |

W≤30W +0.2~+0.6

W>30 W +0.2~+0.8 |

L<100L 0~+1.0

L≥100 L 0~+2.0

L=330 L 0~+5.0 |

| 1.5*(2-10)*L | |||

| 2*(4-15)*L | |||

| 3*(3-20)*L | |||

| 4*(4-30)*L | |||

| 5*(4-40)*L | |||

| 6*(5-40)*L | |||

| (7-20)*(7-40)*L | |||

| Besides the specifications mentioned above, special specifications can be supplied according to your requirements. | |||

FAQ

Yes, we can customize for you as your requirements.

Generally it is 3~5 days if the goods are in stock; or it is 10-25 days if the goods are not in stock, depending on order quantity.

Generally we don’t provide free samples. But we can deduct sample cost from your bulk orders.

Always a pre-production sample before mass production; Always final Inspection before shipment .