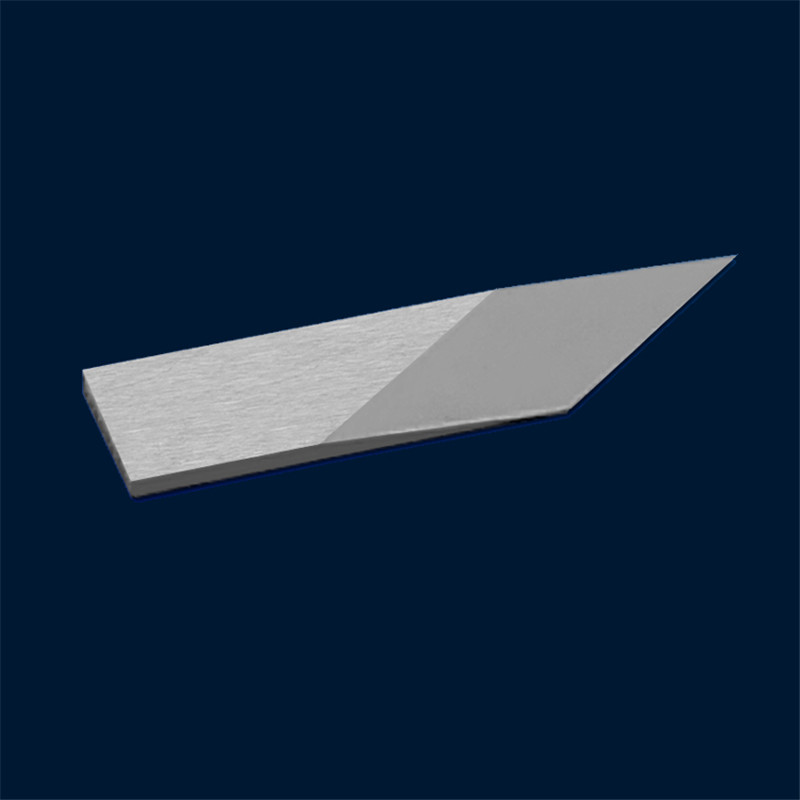

Tungsten Carbide Plotter Blade for digital cutter

Tungsten Carbide Vibrating Knife

Material:100% Virgin Tungsten Carbide,Tungsten Steel

Application Tool:Vibrating knife

Application Industry:Advertising,Composite Materials,Automotive interiors

Cutting Materials:Chevron board,Corrugated paper,Gasket material,PE,XPE,PU Leather,PU Composite sponge,Wire loop,etc

Advantages of Tungsten Carbide blade:

>>1. Improved durability and wear-life, up to 600% better than standard steels;

>>2. Greater productivity and less down time due to fewer blade changes;

>>3. Cleaner and more precise cuts due to reduced friction;

>>4. Reduction in start-up and end of line waste;

>>5. Better overall cutting performance in high heat and high speed cutting environments.

HIP Process

Fine porosity would be remained in Powder metallurgy of processing for Tungsten Carbide, which will be the beginning of destroy of products.

To remove this fine porosity, CARBIDE produce products through HIP Process.

This process is progressed under the high temperature and pressure, and put the identical pressure on whole surface of product.

At this time, a fine porosity would be removed, and effected on improving high strength. You can see it on below graph.

Process flow diagram:

The tungsten carbide blades produced and sold by Chengdu Cemented Carbide Co., Ltd. are made of high-quality cemented carbide materials, which are sharp and durable. They are widely used in flexible materials, paper, corrugated, gray board, hollow board, KT board, and honeycomb. , Leather, leather, cloth and other materials. To meet the production needs of flexible materials, the company’s products are exported to oversea. The quality of the products is excellent and has won good feedback from customers!