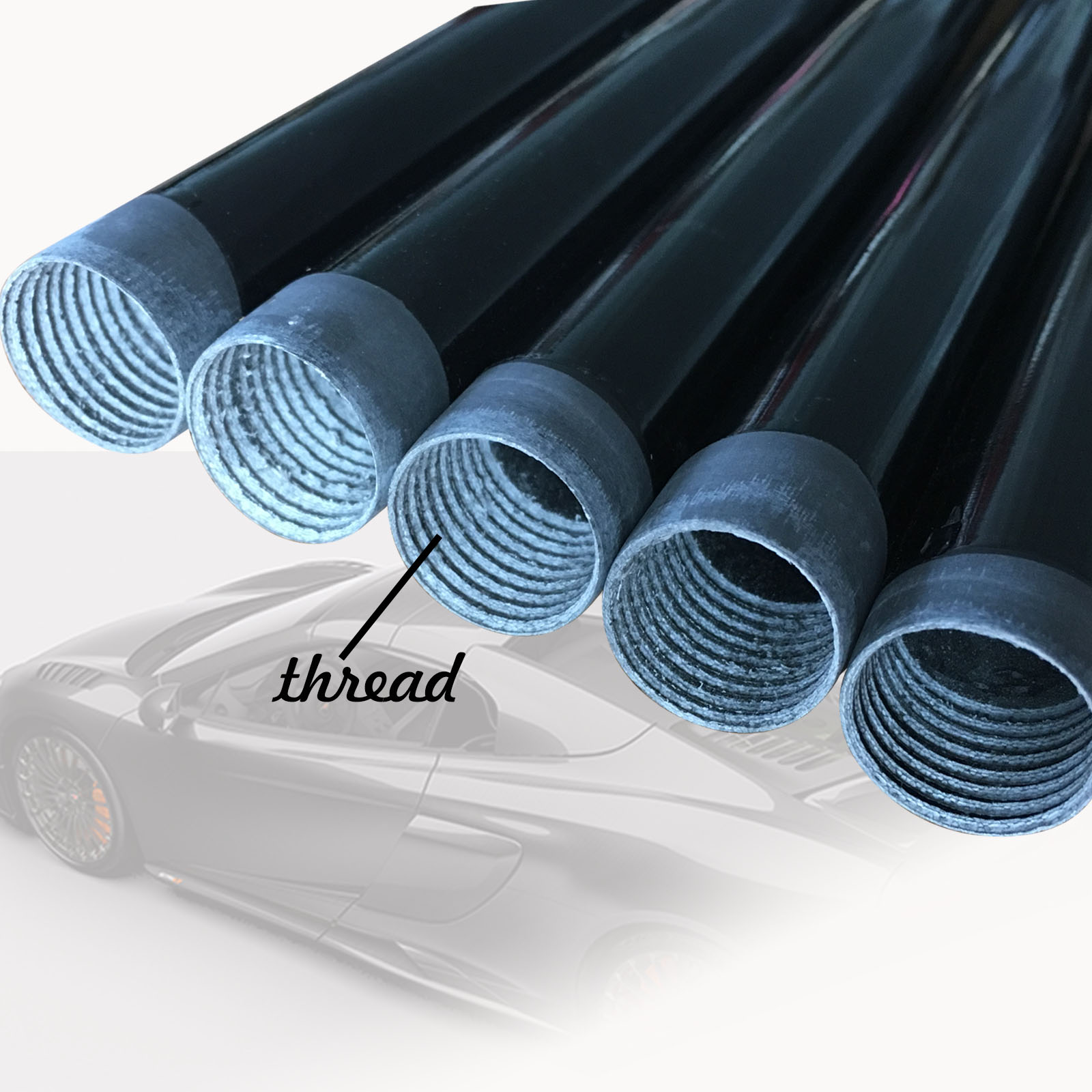

Tungsten Carbide Steel Wire Drawing Dies

Our dies are available with both brazed and interchangeable tungsten carbide insert.We supply exchgeable inserts both round of square,Rond inserts can be supplied with up to three profiles. With more than 17 years experience of tool manufacturing in carbide and steel material for nail machines. In this period,We have gained a good knowledge of the machine wypes for which these tools are supplied,as well as the expertise to know which grade of carbide best suits each tool type. Tools for nail making machine are :Gripper dies Cutter dies Header dies Thread rolling dies

- Versatility: Ranging from 0.1mm to 30mm, TC drawing dies can be manufactured to different shapes, used for a wide range of applications and can withstand high temperatures and pressures. They are also suitable for drawing various types of wire materials.

- Efficiency: Cemented carbide wire drawing dies have a high accuracy and consistency, which improves the quality of the wire products and reduces waste.

- Cost-Effective: TC drawing dies have lower price than other materials dies, they also require less maintenance and can increase productivity. So TC drawing dies are one of the most cost-effective way.

Some of the wear products that we manufacture from tungsten carbide are:

1. Crusher tips and jaws

2. Conveyor scraper blade tips

3. Shot blast nozzles, lance tips, wheel blades

4. Tipped static and rotary recycling shredding blades

5. Impact and wear plates

6. Faced bar hammers

Tungsten Carbide can make as per your request, once detailed application and drawing can be provided. High wear resistance and durable performance can be reached with sufficient communication.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.