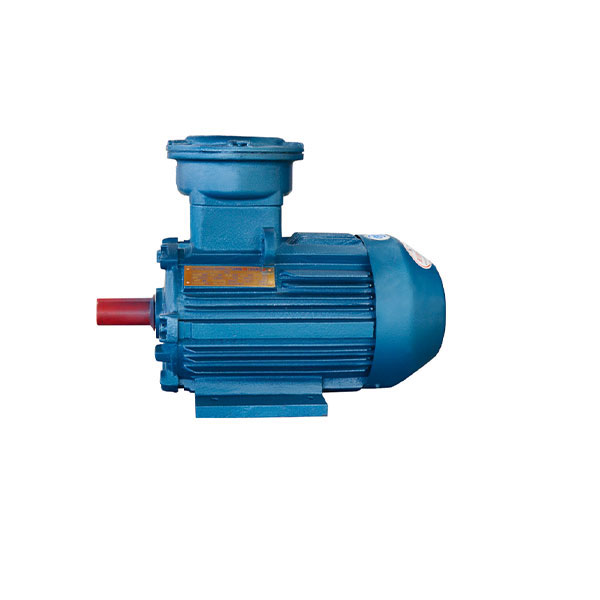

TYB Series Explosion-proof Low Voltage Super High Efficiency Three-phase Permanent Magnet Synchronous Motor For Coal Mine Use(380V, 660V, 1140V H132-355)

Product description

This series of products is designed according to Q/MT005-2019 “TYB Series Mine Explosion Proof Three Phase Permanent Magnet Synchronous Motor”, and is a fully enclosed self fan cooling structure with a protection level of IP55F insulation and S1 working system. The explosion-proof mark is Ex db I Mb.

The rated frequency of this series of products is 50Hz, and the rated voltage is 380V, 660V, or 1140V. It has the ability to self start and can also be started with variable frequency.

This series of products has a temperature rise of 30-50K for motors within the load range of 25% -120%. Compared to asynchronous motors of the same specification, they have higher efficiency, wider economic operating range, and significant energy-saving effects. The temperature rise of the motor is low, and under rated load, the temperature rise of the motor is 30-50K.

This series of products can completely replace series YB2, YB3, and other low-voltage explosion-proof three-phase asynchronous motors, and can also be specially designed according to user needs.

This series of products has three complete certificates: Conformity Certificate Of Explosion-proof, Safety Certificate Of Opproval For Mining Products, and China National Compulsory Certification. This series of products is widely used in various equipment such as underground drag fans, pumps and belt conveyors in coal mines.

Product features

1. High power factor of the motor, high quality factor of the grid, no need to add power factor compensator, the capacity of the substation equipment can be fully utilised;

2. Permanent magnet motor is permanent magnet excitation, synchronous operation, there is no speed pulsation, in dragging fans, pumps and other loads do not increase the pipeline resistance loss;

3. According to the needs of permanent magnet motor can be designed into high starting torque (more than 3 times), high overload capacity, so as to solve the phenomenon of “big horse pulling small cart”;

4. The reactive current of ordinary asynchronous motors is generally about 0.5 to 0.7 times the rated current, permanent magnet synchronous motors do not require excitation current, the difference between reactive current permanent magnet motors and asynchronous motors is about 50%, the actual running current is about 15% lower than that of asynchronous motors;

5. The motor can be designed to start directly, the shape and installation size is the same as the current widely used asynchronous motor, can fully replace the asynchronous motor.

Permanent magnet motor efficiency map

Asynchronous motor efficiency map

Product Application

The series products are widely used in various equipment such as fans, pumps and belt machines in petrochemical, steel, aluminium processing, grain and oil, feed and other fields.

FAQ

What are the advantages of permanent magnet synchronous motors?

1.High motor power factor, high grid quality factor, no need to add power factor compensator;

2.High efficient with low energy consumption and high power saving benefits;

3.Low motor current, saving transmission and distribution capacity and reducing overall system costs.

4.The motors can be designed for direct starting and can fully replace asynchronous motors.

5.Adding the driver can realize soft start, soft stop, and infinitely variable speed regulation, and the power saving effect is further improved;

6.The design can be targeted according to the requirements of the load characteristics, and can directly face the end-load demand;

7.The motors are available in a multitude of topologies and directly meet the fundamental requirements of the mechanical equipment in a wide range and under extreme conditions; the

8.The aim is to increase system efficiency, shorten the drive chain and reduce maintenance costs;

9.We can design and manufacture low speed direct drive permanent magnet motors to meet the higher requirements of users.

Technical characteristics of permanent magnet motors?

1.Rated power factor 0.96~1;

2.1.5%~10% increase in rated efficiency;

3.Energy saving of 4%~15% for high voltage series ;

4.Energy saving of 5%~30% for low voltage series ;

5.Reduction of operating current by 10% to 15%;

6.Speed synchronization with excellent control performance;

7.Temperature rise reduced by more than 20K.