Vacuum Casting for Flexible and Economic Production

Why Vacuum Casting

Unmatched Lead Time

Complex Geometries Support

Flexible Color Options

Material and Finishing Selection

Consistent Quality

Professional Vacuum Casting Specialists

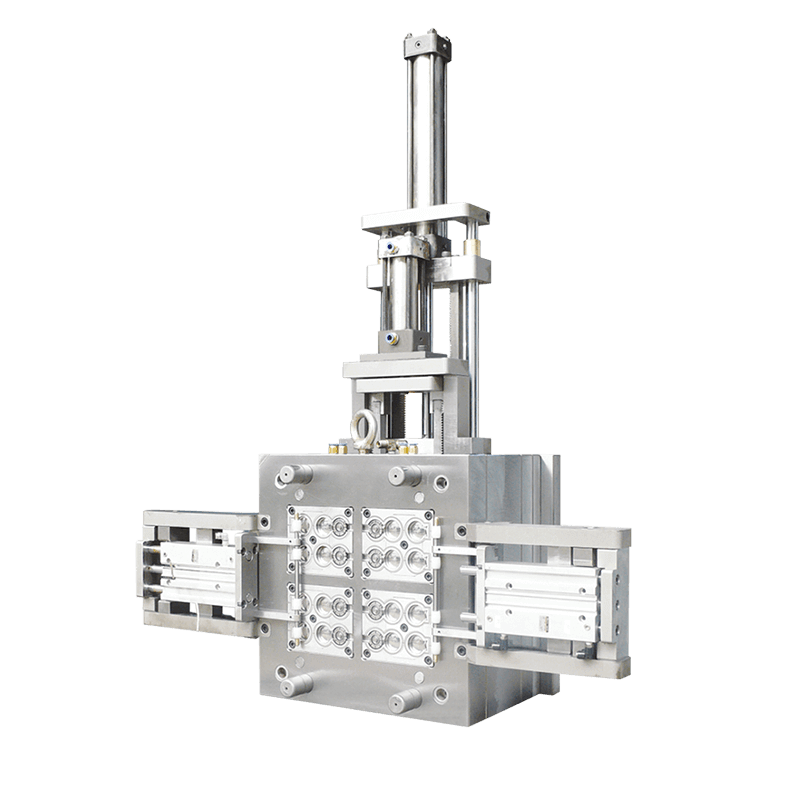

Vacuum Casting from Prototyping to Production

Vacuum molding is the perfect option for fabricating top-notch mock-ups and small-volume components for various uses. Our support assists in achieving your production targets.

Prototyping

Market Testing

On-Demand Production

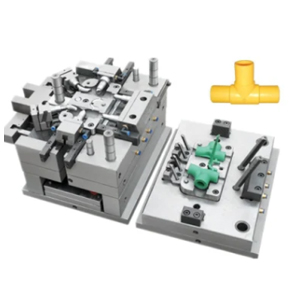

Vacuum Casting Materials

You have options for vacuum casting materials based on your project’s specifics. Usually, these resins resemble standard plastics in performance and look. Our urethane casting materials are categorized to guide your project decisions effectively.

PS

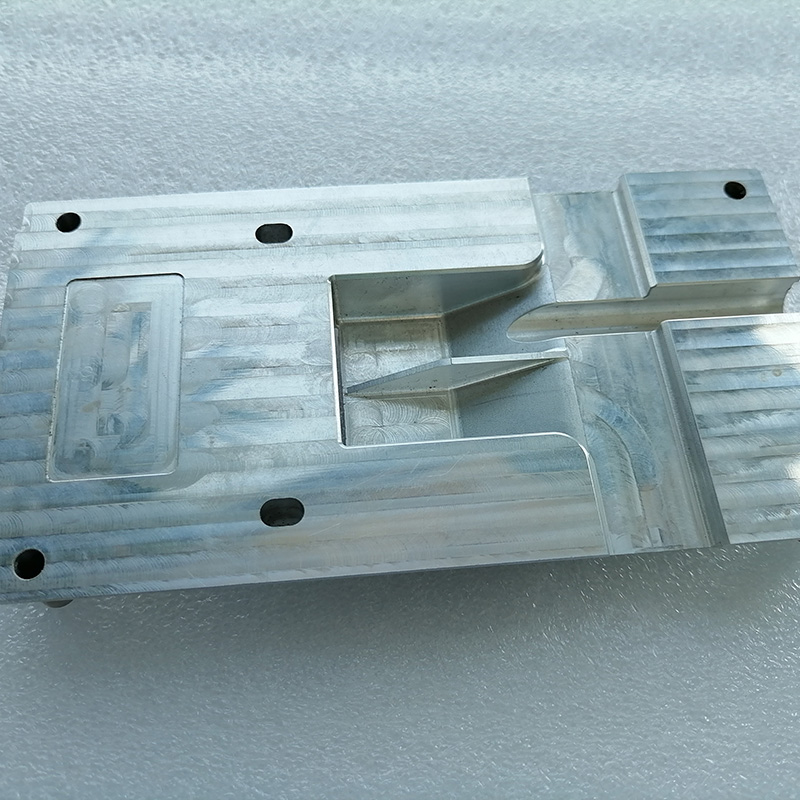

Surface Finish for Vacuum Casted Parts

Breton Precision has a wide range of surface coatings, allowing for the production of distinct surface layers on your vacuum casting components. These coatings assist in fulfilling the aesthetic, strength, and chemical resistance needs of your products. Various surface finishes are available based on the materials chosen and component functions.

| Available Finishing | Description | SPI Standard | Link | |

| High Gloss | The gloss of the created surface finish is highly reflective after the polish of the male mold before making the mold. This high-gloss finish provides high transparency and is beneficial for cosmetic pieces, lenses, and other surfaces that can be easily cleaned. | A1, A2, A3 | ||

| Semi Gloss | This B level finish doesn’t reflect light strongly yet provides a bit of luster. By utilizing rough sandpaper, smooth, washable surfaces can be achieved, falling between high-shine and dull. | B1, B2, B3 | ||

| Matte Finish | Vacuum cast parts can attain a satin-like appearance by using bead or sand blasting on the original mold. Such C-tier finishes are well-suited to spots frequently touched as well as handheld parts. | C1, C2, C3 | ||

| Custom | RapidDirect is able to offer personalized finishes using supplementary methods. If desired, distinctive secondary finishes can be obtained to achieve optimal outcomes. | D1, D2, D3 |

Vacuum Casting Tolerances

Breton Precision provides various vacuum molding tolerances for your specific needs. According to the original design and component structure, we are capable of achieving dimensional tolerances from 0.2 to 0.4 meters. Here are the detailed specifications for our vacuum molding services.

|

Type |

Information |

|

Accuracy |

Highest precision to reach ±0.05 mm |

|

Max Part Size |

+/- 0.025 mm +/- 0.001 inch |

|

Minimum wall thickness |

1.5mm~2.5mm |

|

Quantities |

20-25 copies per mold |

|

Color & Finishing |

Color and texture can be customized |

|

Typical Lead Time |

Up to 20 parts in 15 days or less |