As far as the high rigidity structure is concerned, the finite element analysis software has been used for auxiliary design, static and dynamic structure analysis of the casting, which ensures the high rigidity of the whole structure.

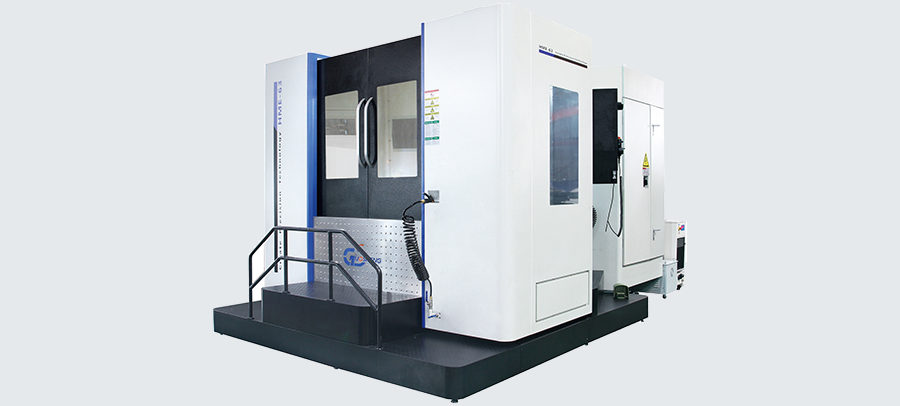

VM series Vertical Machining Center

| Standard Configuration | Optional Configuration |

| Vertical Type | |

| FANUC CNC system | FANUC/Siemens/Heidenhain CNC Controller |

| BT40 12000rpm Spindle | BT/ISO/HSK-A63 10000~30000rpm Spindle |

| Spindle Direct Drive | |

| Spindle Oil Chiller | |

| Spindle coolant nozzle system | Coolant Through Spindle (CTS) |

| High Precision Screw rod | Coolant Through Screw rod |

| P-level roller Linear guide | |

| XYZ Axis Servo Motor | |

| Fully Enclosed Splash Guard | |

| Electrical Cabinet Heat Exchanger | Electrical Cabinet AC |

| Handheld air gun | |

| Water gun | |

| Automatic chip cleaning | |

| Automatic lubrication system | |

| LED working lamp | |

| Tool magazine | ATC/Tool Magazine system |

| CNC Manual & Operation | |

| Chip flush coolant system | |

| LCD | |

| Working lamp | |

| Three-color warning lamp | |

| Transformer(According to Local Voltage) | |

| Took kit | |

| The 4th axis rotary table | |

| spiral type Chip Conveyor system | |

| Chain type Chip Conveyor system | |

| Linear Scale | |

| Auto.Tool Measuring system | |

| Auto.Workpiece Measuring system | |

| CE Mark | |

| Others Options as requested |

-

High Rigidity of Columns

High Rigidity of Columns

-

High Precision Linear guide

High Precision Linear guide

The X Y Z axis adopt heavy duty linear roller guide rail. They are of good rigidity, high accuracy and long service life

-

Compensation system for Z axis temperature (Optional) Z

Compensation system for Z axis temperature (Optional) Z

-

Drive base integrated casting

Drive base integrated casting

-

Diluted lubrication for screw support bearing

Diluted lubrication for screw support bearing

-

Full automatic rear chip cleaning structure

Full automatic rear chip cleaning structure

- Previous: V GENERAL VERTICIAL MACHINING CENTER

- Next: GMB 5-AXES GANTRY MACHINING CENTER

-

Parameter table

VM Series Vertical Machining Center Machine Type Unit VM960 VM1165 VM1270 Worktable Worktable mm 1000×600 1200×650 1300×700 Worktable T-slot mm 5-18×120 Worktable load kg 900 1200 1200 Itinerary Triaxial itinerary(X×Y×Z) mm 900×600×600 1100×650×700 1200×700×700 Distance from spindle center to column guide surface mm 715 765 815 Distance from spindle nose to table surface mm 100-700 100-800 100-800 Spindle Spindle speed rpm 15000 15000 15000 Tool holder specification BT40 BT40 BT40 Main motor power kW 9/11/15 9/11/15 9/11/15 Feed speed Fast feed speed(X×Y×Z) m/min 30/30/30 30/30/24 30/30/24 Tool magazine Tool magazine capacity 24 24 24 Maximum tool diameter mm φ80 φ80 φ80 Maximum tool length mm 300 300 300 Maximum tool weight kg 8 8 8 Tool changing time sec 2.5 2.5 2.5 Precision Positioning accuracy mm 0.008 0.008 0.008 Repeated positioning accuracy mm 0.005 0.005 0.005 Numerical control system Numerical control system FANUC-0i MF FANUC-0i MF FANUC-0i MF Total capacity of machine tool power supply KVA 25 35 35 Air supply Air supply pressure bar 6-8 6-8 6-8 Air pressure flux L/min 280 280 280 Others Machine tool weight kg 7000 8000 8500 Overall dimension(length×width×height) mm 2660×3000×3150 3100×3300×3500 3100×3300×3500 -

High Rigidity of Columns

High Rigidity of Columns

As far as the high rigidity structure is concerned, the finite element analysis software has been used for auxiliary design, static and dynamic structure analysis of the casting, which ensures the high rigidity of the whole structure.

-

High Precision Linear guide

High Precision Linear guide

The X Y Z axis adopt heavy duty linear roller guide rail. They are of good rigidity, high accuracy and long service life

-

Compensation system for Z axis temperature (Optional) Z

Compensation system for Z axis temperature (Optional) Z

-

Drive base integrated casting

Drive base integrated casting

-

Diluted lubrication for screw support bearing

Diluted lubrication for screw support bearing

-

Full automatic rear chip cleaning structure

Full automatic rear chip cleaning structure

- Vertical Cnc Drilling Machin

- Vertical Cnc Machining Center

- Vertical Cnc Milling Machin

- Vertical Drilling Machin

- Vertical Machining Center

- Vertical Mill

- Vertical Milling Machine

Write your message here and send it to us