Waste Plastic Polystyrene foam recycling machine

working process

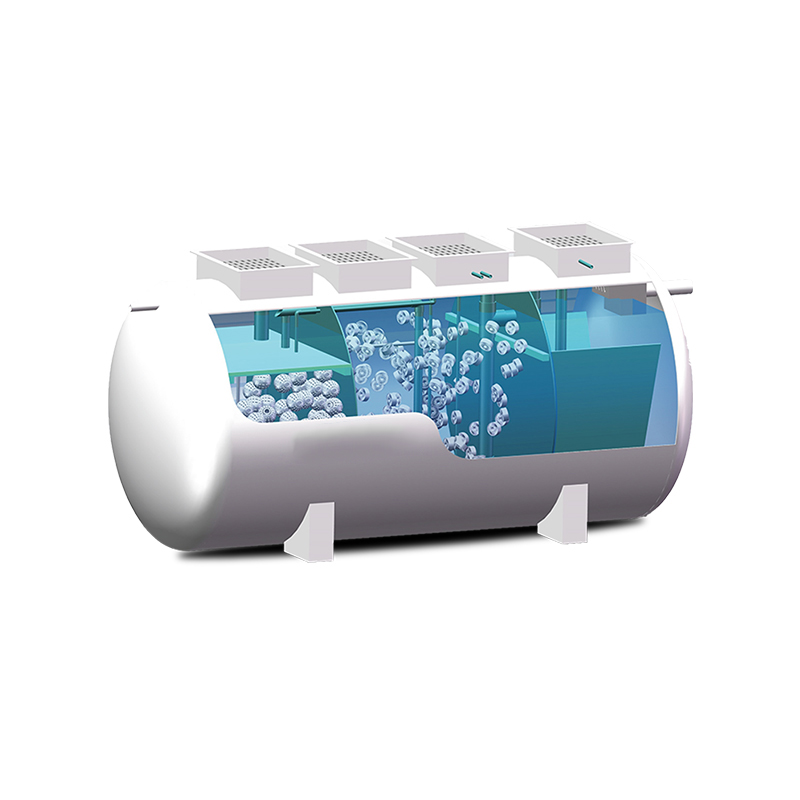

machine description

The whole machine consists of crusher, main machine, cooling tank and granulator. Its equipped with quick motor-operated filter-screen-replacing unit and automatic temperature control.It adopts single screw, double stage plasticification, increasing compress ratio.

lt is the ideal equipment to recycle the waste materials It features compact structure and easy operation.

This line is of new design, reasonable configuration, steady operation, low noise, low consumption and high output.

Crush Part

blades made of special material, with high hardness

easy operation to change blades or screen mesh

high capacity with stability

Recycle Part

The waste plastic is heated and melted by the hot air, and the melted plastic melt is extruded and granulated through the screw, so the noise and dust are avoided, and the working conditions of the workers are improved; through Controlling the temperature of the hot air can prevent the plastic from degrading due to excessive temperature during the melting process, and the hot air can be recycled, which reduces energy consumption.

Electric Cabinet

It adopts Frequency exchanger,Electronic component and Temperature controller.Independent electrical cabinet control system, easy to operate and control, install equipment, troubleshoot, etc.

Finished product

It can recycle many foamed products, such as ps, xps, eps, pe etc.

With its light weight, high strength, corrosion resistance, easy processing and other excellent properties.Waste plastics are difficult to degrade naturally, which will cause environmental pollution and waste of resources. Plastic waste recycling is a way to turn waste into treasure, and the waste plastic granulator is a powerful assistant to solve the ecological environment pollution.