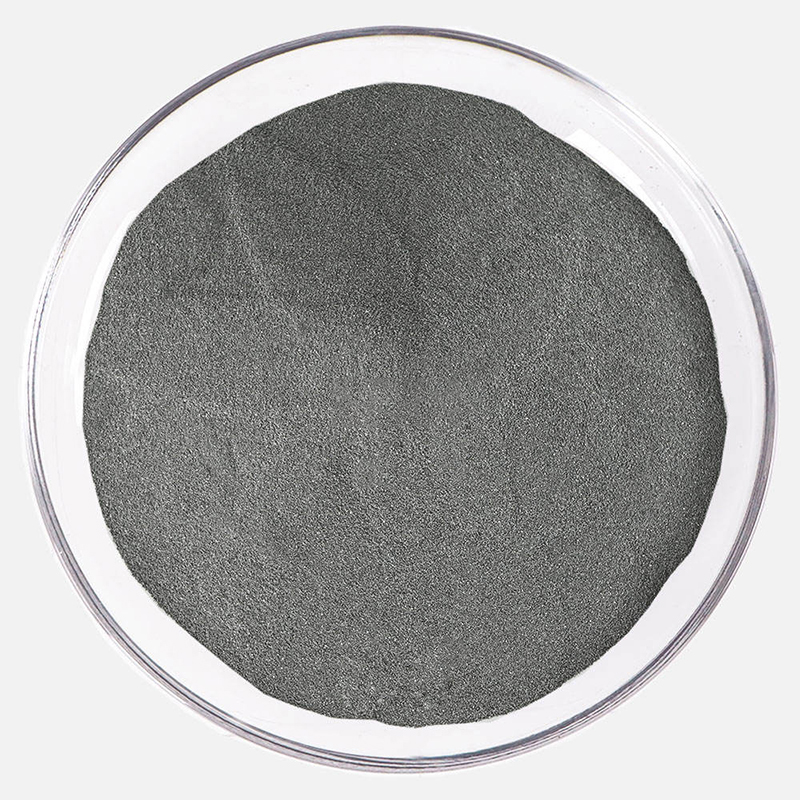

WC-10Ni Powder WC Based Powder for Thermal Spray

Product Description

WC-10Ni is a tungsten carbide based powder containing nickel, using the agglomerating and sintering process. It has excellent resistance to corrosion, wear and slip wear. Compared with WC-Co, WC-Ni has higher hardness and lower toughness, but better corrosion resistance, which is widely used in ball valves, gate valves, and oilfield equipment. Since it does not contain cobalt, it may be used in radioactive environments.

Specification

| Product Name | WC-Ni Powder |

| Grade | 90/10 |

| Process | Agglomerated & Sintered |

| Flow Density | 4.3-4.8 Typical 4.5 |

| Size | 5-30um; 10-38um; 15-45um; 20-53um; 45-90um |

| Hardness | HV 600-800 Deposit efficiency 50-60% |

| Application Data | HVOF Better corrosion protection than WC-Co Superior deposition efficiency Used for fan blades, pump components, dies, valve seats, oil field apparatus and other erosion, abrasion and sliding wear applications |

Related Products

| Grade | WC-Co | WC-Co | WC-CoCr | Cr3C2-NiCr | WC-CrC-Ni |

| Production process | Agglomerated & Sintered | ||||

| Radio | 88/12 | 83/17 | 86/10/4 | 25/75 | 73/20/7 |

| Density | 4.3-4.8 | 4.3-4.8 | 4.3-4.8 | 2.3-2.8 | 4.3-4.8 |

| Typical 4.5 | Typical 4.5 | Typical 4.5 | Typical 2.5 | Typical 4.5 | |

| Hardness | HV 1000/1200 |

HV 850-1050 |

HV 1000/1200 |

HV 700-900 |

HV 1200-1300 |

| Deposit efficiency | 50-70% | 50-70% | 50-70% | 50-60% | 50-60% |

| Size | 5-30um | 5-30um | 5-30um | 5-30um | 5-30um |

| 10-38um | 10-38um | 15-45um | 10-38um | 10-38um | |

| 15-45um | 15-45um | 10-38um | 15-45um | 15-45um | |

| 20-53um | 20-53um | 20-53um | 20-53um | ||

| 45-90um | 45-90um | 45-90um | 45-90um | ||

Quality control system

has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.