Wooden Floor AC2, HDF AC3, AC4 laminate flooring waterproof EIR surface, super anti-scratch

Description

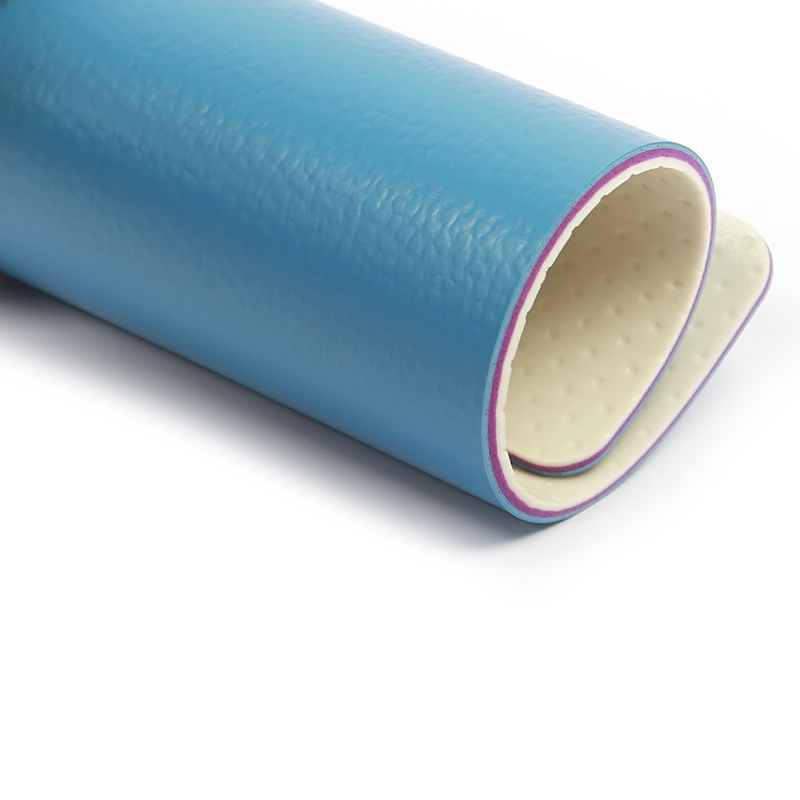

STRUCTURE PICTURE:

Large Size Laminate Flooring

Colors carefully selected reducing pattern repetition, stronger wood flooring feeling visually, It looks more elegant and luxury with large plank size .Compared with real wood flooring, this product is scratch-resistant, easy to maintain, and cost-effective.

EIR Laminate Flooring

With EIR surface effect, it looks more realistic of solid wood feeling, which has classic colors and updated new colors each year.

Herringbone on Laminate flooring

Imitation real wood visual effect, rich installation methods to meet user’s diverse needs.

AVAILABLE SIZES INFORMATION:

Thickness: 6mm, 7mm, 8mm,10mm, 12mm

Length and width: 1215x195mm, 1215x128mm, 1215x168mm, 808x130mm, 2450x195mm

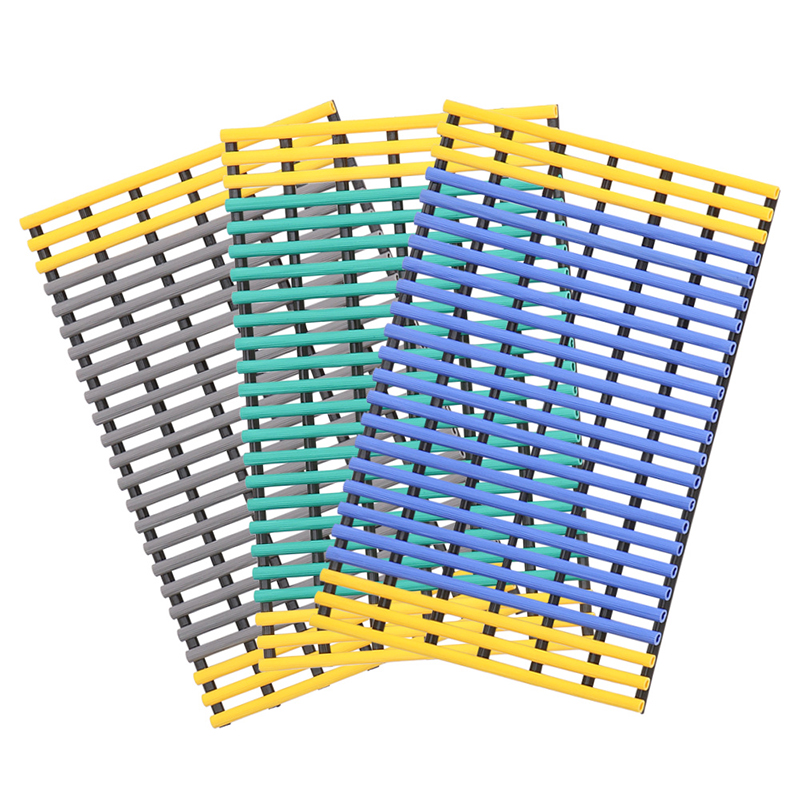

Application

APPLICATION SCENARIO

Education use: school, training center, and nursery school etc.

Medical system: hospital, laboratory and sanatorium etc.

Commercial use: Hotel, restaurant, shop, office, and meeting room.

Home use: Living room, kitchen, and study room etc.

DURABLE:

Wear resistance, scratch resistance, stain resistance

SAFETY:

Slip resistant, fire resistant and insect proof

CUSTOM –PRODUCT:

Product size, décor color, product structure, surface embossing, core color, edge treatment, the gloss degree and function of UV coating can be customized.

W Choose Us

Advantages for Laminate flooring

- Abrasion Resistant

- Moisture Resistant

- Deluxe wood grain textures

- Durable decors

- Dimension stable and perfect fit

- Easy install and maintenance

- Stain resistant

- Flame resistant

Our capacity:

- 4 profiling machine line

- 4 full auto pressure sticking machine line

- Annual capacity up to 10million sq m.

Guarantee:

-20years for residential,

10years for commercial

Technical data

Date : Feb 20, 2023

Page: 1 of 8

| CUSTOMER NAME: | AHCOF INTERNATIONAL DEVELOPMENT CO. LTD. |

| ADDRESS: | AHCOF CENTER, 986 GARDEN AVENUE, HEFEI, ANHUI, CHINA |

| Sample Name | LAMINATE FLOORING |

| Product Specification | 8.3mm |

| Material and Mark | Wood fiber |

| Other Information | Type No.: 510;Colour: Earth-yellow |

Above information and sample(s) was/were submitted and confirmed by the client. SGS, however,

assumes no responsibility to verify the accuracy, adequacy and completeness of the sample

information provided by client.

| *********** | |

| Date of Receipt | Feb 07, 2023 |

| Testing Start Date | Feb 07, 2023 |

| Testing End Date | Feb 20, 2023 |

| Test result(s) | For further details, please refer to the following page(s) |

(Unless otherwise stated the results shown in this test report refer only to the sample(s) tested)

Signed for

SGS-CSTC Standards Technical

Services Co.,Ltd Xiamen Branch

Testing Center

Bryan Hong

Authorized signatory

Date : Feb 20, 2023

Page: 3 of 8

| No. | Test item(s) | Test method(s) | Test condition | Test result(s) | ||

| 8 | Abrasion resistance |

EN 13329:2016 +A2:2021 Annex E |

Specimen: 100mm×100mm, 3pcs Type of wheel: CS-0 Load: 5.4±0.2N/wheel Abrasive paper: S-42 |

Average abrasion cycles: 2100 cycles, Abrasion class AC3 |

||

| 9 | Impact resistance (Large ball) |

EN 13329:2016 +A2:2021 Annex H |

Specimens: 180mm×180mm×8.3mm, 6pcs Mass of steel ball: 324±5g Diameter of steel ball: 42.8±0.2mm |

Impact Height: 1500mm, no visible damage. |

||

| 10 | Resistance to staining |

EN 438-2: 2016 +A1:2018 Section 26 |

Specimen: 100mm×100mm×8.3mm, 5pcs |

Rating 5: No change (See Annex A) |

||

| 11 | Castor Chair Test |

EN 425:2002 | Load: 90kg Type of castors: Type W Cycles: 25000 |

After 25000 cycles, no visible damage |

||

| 12 | Thickness swelling |

ISO 24336:2005 | Specimen: 150mm×50mm×8.3mm, 4pcs |

13.3% | ||

| 13 | Locking strength |

ISO 24334:2019 | Specimen: 10 pieces of long side (X direction) specimens 200mm×193mm×8.3mm, 10 pieces of short side (Y direction) specimens 193mm×200mm×8.3mm Loading rate: 5 mm/min |

Long side(X): 2.7 kN/m Short side(Y): 2.6 kN/m |

||

| 14 | Surface soundness |

EN 13329:2016 +A2:2021 Annex D |

Specimen: 50mm×50mm, 9pcs Bonding area: 1000mm2 Testing speed: 1mm/min |

1.0 N/mm2 | ||

| 15 | Density | EN 323:1993(R2002) |

Specimen: 50mm×50mm×8.3mm, 6pcs |

880 kg/m3 | ||

| Note (1): All test specimens were cut from the samples, see the photographs. | ||||||

| Note (2): Abrasion class according to EN 13329:2016+A2:2021 | Annex E Table E.1 as follow: | |||||

| Abrasion class | AC1 | AC2 | AC3 | AC4 | AC5 | AC6 |

| Average abrasion cycles |

≥500 | ≥1000 | ≥2000 | ≥4000 | ≥6000 | >8500 |

Date : Feb 20, 2023

Page: 4 of 8

Annex A: Result of the resistance to staining

| No. | Stain agent | Contact time | Result – Rating | |

| 1 | Group 1 | Acetone | 16h | 5 |

| 2 | Group 2 | Coffee (120g coffee per litre of water) | 16h | 5 |

| 3 | Group 3 | Sodium droxide 25% solution | 10min | 5 |

| 4 | Hydrogen peroxide 30% solution | 10min | 5 | |

| 5 | Shoe Polish | 10min | 5 | |

| Descriptive numerical rating code: | ||||

| Numerical rating |

Description | |||

| 5 | No change test area indistinguishable from adjacent surrounding area |

|||

| 4 | Minor change | |||

| test area distinguishable from adjacent surrounding area, only when the light source is |

||||

| mirrored on the test surface and is reflected towards the observer’s eye, e. g. | ||||

| discoloration, change in gloss and colour | ||||

| 3 | Moderate change | |||

| test area distinguishable from adjacent surrounding area, visible in several viewing directions, e. g. discoloration, change in gloss and colour |

||||

| 2 | Significant change | |||

| test area clearly distinguishable from adjacent surrounding area, visible in all viewing |

||||

| directions, e. g. discoloration, change in gloss and colour, and / or structure of the surface slightly changed, e.g. cracking, blistering |

||||

| 1 | Strong change | |||

| the structure of the surface being distinctly changed and / or discoloration, change in gloss and colour, and / or the surface material being totally or partially delaminated |

||||